When it comes to manufacturing, injection moulding is considered one of the most important processes for mass production of a wide range of products with complicated shapes. Although the process involves clamping, injection, dwelling, cooling, mould opening, and removal of products, the journey of injection moulds is an intricate process that includes design, production, as well as innovation. Let’s explore the fascinating journey of injection moulds in China.

Design Phase

The injection moulding journey starts with careful engineering and design. Expert designers create complex and accurate mould designs that meet the requirements of the product intended using sophisticated CAD (Computer-Aided Design) software. Moreover, to ensure the best possible performance and manufacturability, every factor is carefully considered, including part geometry, material selection, and tooling concerns.

Prototype Development

Prototype development is essential for verifying the functionality and design of injection moulds before moving forward with mass manufacturing. In this case, 3D printing proves to be a useful tool in the industrial toolbox. Prototypes may be quickly created from digital designs using additive printing technology, enabling designers and engineers to test ideas, confirm measurements, and find any problems before moving on with full-scale production. Modern printers that can quickly and accurately produce high-quality prototypes are installed at 3D printing facilities, which speeds up the product development process.

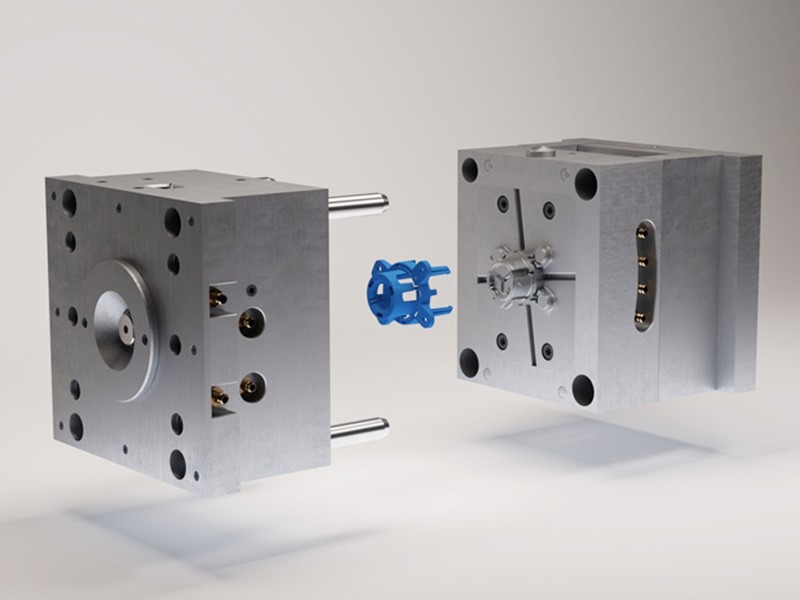

Tooling and Manufacturing

Typically, injection moulding in China creates moulds using CNC (Computer Numerical Control) machining processes from sturdy materials like steel or aluminium. Expert craftsmen carefully form and polish the mould cavities in accordance with precise measurements, guaranteeing accurate reproduction of the intended pieces.

Injection Moulding Process

The injection moulding process starts after the moulds are prepared for manufacture. High pressure is used to inject molten thermoplastic or thermosetting resins into the mould cavities. Consequently, the mould opens and the completed components are ejected, ready for assembly or further processing, once they have cooled and hardened. Moreover, modern technologies including robotic automation and servo-driven systems are installed in China's injection moulding equipment, allowing for precise control, rapid production, and reliable quality.

Quality Control

Strict quality control methods are applied at every stage of the production cycle, from checking the final product to inspecting the raw materials. The use of sophisticated metrology apparatus and testing procedures ensures that every component satisfies the necessary requirements by validating mechanical attributes, dimensional correctness, and other crucial criteria.

Constant Improvement

With the change in demands as well as technology, manufacturers in China are at the forefront of implementing new methods and procedures to improve productivity, sustainability, and quality. They are driving injection moulding innovation to meet the changing demands of global industries, whether it is through the integration of Industry 4.0 concepts or the adoption of eco-friendly practices.

Lastly, the journey of injection mould in China is proof of the country’s commitment to innovation and excellence in manufacturing. From the design phase to the final product, injection moulds go through a meticulous process. This process is guided by precision, technology, and skilled craftsmanship. Moreover, with the integration of advanced technology like 3D printing, China continues to lead the future of injection moulding.