Innovation is the secret to success in today’s fast-paced manufacturing world. Businesses in all sectors are always trying to develop distinctive items that will help them stand out from the competition. Bespoke China mould manufacturers are essential in this situation. They help businesses realize their ambitious product ideas by offering customized mould solutions, which promotes efficiency and innovation.

Enabling Unique Product Designs

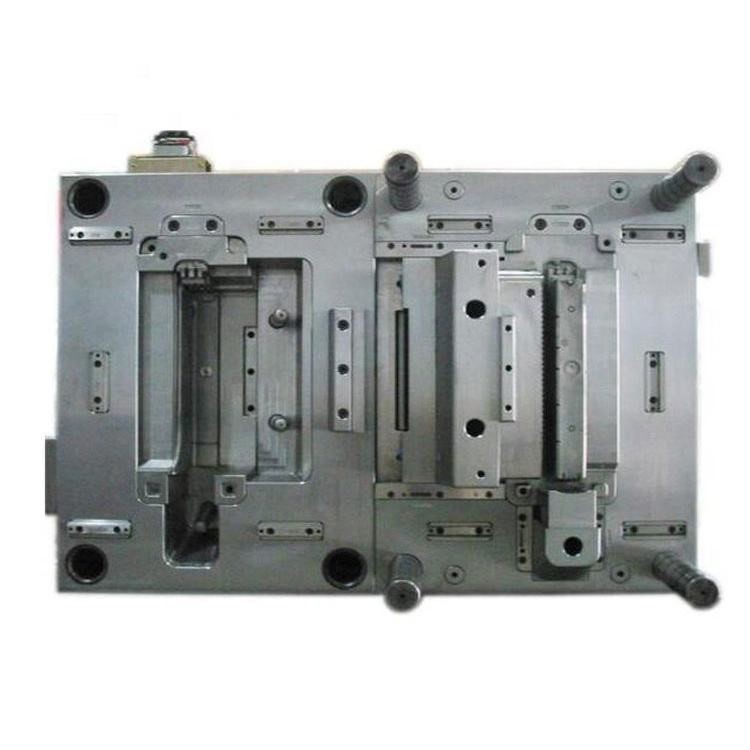

Custom mould manufacturers are experts at making moulds that precisely match a product's specifications. Custom solutions, as opposed to generic moulds, enable complicated designs and exact specifications, ensuring that even the most difficult concepts may be accurately produced. This gives companies the freedom to experiment with design components, investigate innovative concepts, and create unique goods that appeal to their target market.

For instance, the consumer goods, automotive, and medical device industries mainly rely on bespoke moulds to produce items with intricate details and complex geometries. Custom mould production guarantees that the finished product perfectly satisfies both form and function, whether it is a unique automotive part, a specific medical component, or a custom packaging solution.

Speeding Up Innovation with Rapid Prototyping

Innovation often depends on one's capacity for efficient and rapid idea testing. Rapid prototype China is extremely useful in this situation. Rapid prototyping technologies are incorporated into the procedures of custom mould manufacturers, allowing companies to create prototypes in a few days. Businesses can verify their designs, make necessary adjustments, and find defects by developing working prototypes before starting full-scale production.

Time-to-market is shortened by this quicker development cycle, which is essential for maintaining competitiveness. Rapid prototyping is extremely beneficial to industries like electronics, industrial manufacturing, and aerospace since it allows them to quickly develop designs and introduce breakthrough products more quickly than ever before.

Flexibility and Scalability

The flexibility offered by custom mould manufacturers is one of the main benefits of working with them. Custom moulds can be made to meet different production needs, whether a business has to manufacture in small batches or on a large scale. Businesses may test out new product lines without having to pay hefty upfront fees because of its scalability.

Custom moulds also enable design adjustments to be made during production, allowing for product enhancements in response to consumer input. Businesses are guaranteed to stay flexible and responsive to shifting customer needs with this degree of adaptability.

Supporting Industry-Specific Innovations

Custom mould production solves particular problems and demands, enabling advances specific to a given industry. For instance, moulds used in the medical field have to adhere to strict quality and safety regulations. Reliability and compliance are ensured by custom manufacturers who make high-precision moulds for implants and surgical instruments.

Custom moulds make it possible to produce both aesthetically pleasing and useful products in the consumer goods industry, where durability and aesthetics are equally vital. Businesses can provide solutions that are unique in the industry, ranging from svelte electrical devices to ergonomic kitchenware.

Custom mould manufacturers are at the forefront of product innovation, providing companies with the resources they require to realize innovative concepts. They are essential for speeding up product development and guaranteeing market success since they allow for innovative ideas, facilitate quick prototype development, and offer flexibility. Businesses working together with custom mould manufacturers will continue to be a catalyst for innovation as industries change, producing goods that push the envelope and satisfy contemporary needs.