When it comes to large-scale manufacturing, injection molding has emerged as a top choice for businesses looking to create high-quality plastic components effectively. Injection molding is a popular manufacturing process in which parts are created by injecting molten material, usually thermoplastic, into a mold cavity. It is extensively used in the manufacturing of consumer items and automotive components.

Further in this blog, we will explore why injection molding in China provides unparalleled cost-effectiveness if you're just starting to scale production.

With injection molding, the cost per unit decreases significantly as manufacturing volume rises, which is one of its greatest benefits. Although buying molds might be expensive up front, bulk manufacturing soon makes up for this expense. Once the mold is created, the average production cost per part may be greatly reduced by using the mold thousands of times.

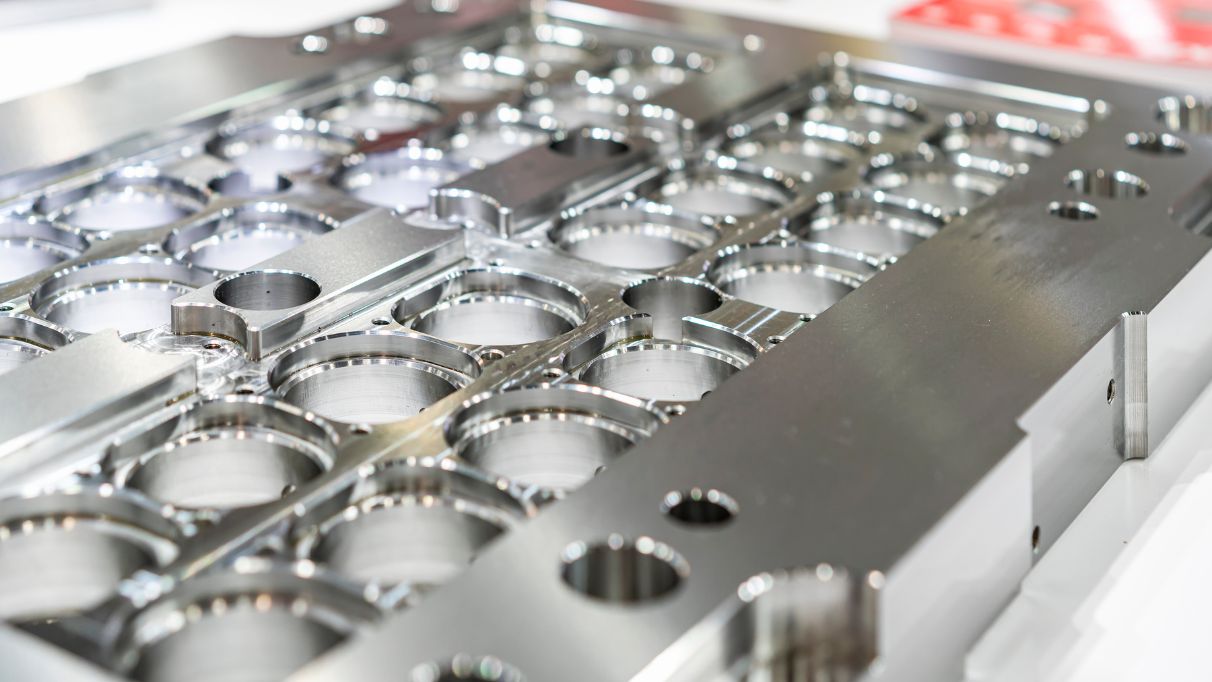

When compared to subtractive production techniques like CNC machining, injection molding produces a lot less waste. The material is precisely pumped into the mold, and any extra is frequently recyclable. Over time, this efficiency promotes sustainable production methods and lowers the cost of raw materials.

Another important component of cost savings is speed. Many pieces may be produced in a matter of minutes by injection molding machines. With this faster manufacturing cycle, labor and energy expenses per unit decrease. Moreover, meeting deadlines with a large volume demand becomes easier.

All units are guaranteed to be uniform and precise with injection molding. A well-designed mold can produce thousands of pieces with little variation. In high-volume manufacturing settings, quality control, rework, and returns may be costly; thus, uniformity lowers those costs.

Because injection molding is so automated, fewer humans are required to manage production. As a result, labor expenses are greatly decreased. Additionally, since machines manage the entire process, from injection to cooling and ejection, with human intervention needed only for maintenance and oversight, operational costs are further reduced.

In mass production scenarios, injection molding in China is renowned for its capacity to provide reliable quality at a reduced expense. From original design to full-scale manufacturing, firms may expedite the whole process by combining CNC production for mold-making and prototyping. The process of injection molding is engineered for scalability, minimizing labor reliance and material waste. So, get ready to combine precision with profit with injection molding.

Which industries benefit from injection molding the most?

Injection molding is used for cost-effective mass manufacturing in a number of crucial sectors, including packaging, consumer electronics, automotive, and medical equipment.

What is the duration required to create an injection mold?

The fabrication of a mold might take two to six weeks, depending on its intricacy. When it's ready, it's utilized to swiftly make thousands of pieces.

Is it possible to utilize recycled plastic for injection molding?

Yes, to save the cost of materials and their influence on the environment, many manufacturers use recycled thermoplastics.

How long does an injection mold last?

Steel molds provide exceptional long-term value and may endure hundreds of thousands of cycles with the right care.

What is the benefit of multi-cavity molds?

Produces many parts in one cycle, spreading mold costs and lowering per-unit price

Ready to cut costs and increase efficiency? Contact UTT Mould’s expert injection molding team in China today for tailored, cost-efficient mass production solutions.