Every product development team requires rapid injection molding as an accelerator in today's fast-paced production environment. The more quickly you can go from idea to finished product, the more competitive you become. Rapid injection molding is a preferred technique for companies looking to save lead times because it provides quick turnaround, high accuracy, and consistent quality. Are you curious about how it improves your time-to-market? Continue reading to find out five solid reasons.

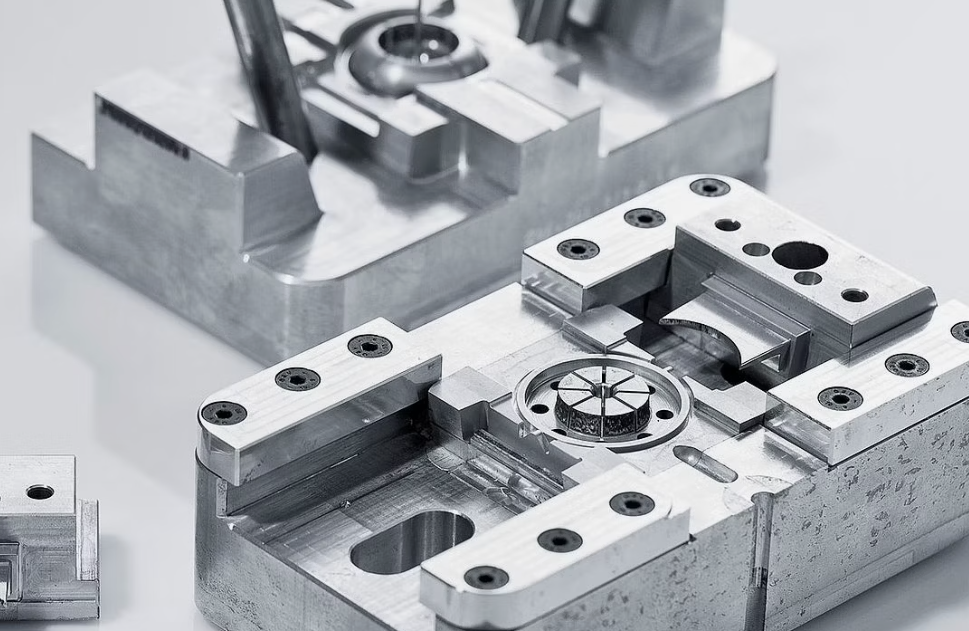

The lengthy tooling procedures involved in traditional molding are eliminated by rapid injection molding. Instead of taking weeks to build, the mold may be made in a matter of days after your design is complete. You may save a significant amount of time during early-stage development or pilot launches by using this simple setup to obtain working prototypes or low-volume manufacturing parts more quickly.

You cannot avoid changes in any cycle of product development. Rapid injection molding allows designers to test, get feedback, and make changes in real time without halting the process. Without adding extra time to your development schedule, these rapid prototyping capabilities guarantee that the finished product is functional, optimized, and ready for the market.

Following approval of a prototype, manufacturing can quickly grow. Without requiring major process adjustments, rapid injection molding enables you to smoothly transition from low-volume runs to larger numbers. Your team will be able to respond to consumer demands quickly and accurately with this flexibility, which enables pilot projects and product launches.

Quality control is a major component that reduces time to market. With rapid injection molding, high-tolerance molds provide consistency throughout all parts. By supporting a large variety of thermoplastics, the technique gives producers the assurance that each component will function in the same way, cutting down on inspection and rework time.

Making traditional molds is costly and time-consuming. Aluminum molds, on the other hand, are more affordable and easier to construct for shorter production cycles in rapid injection molding. With this, you save time and money, two important factors in a successful product launch.

Rapid injection molding is more than just a technique; it's a competitive strategy in a world where speed can make or break a product launch. It gives teams the confidence to test, launch, and iterate. Additionally, don't overlook sheet metal prototyping as an additional option for quick, accurate component creation if you're working on multi-component assemblies.

Can intricate geometries be handled by rapid injection molding?

Yes, it works well for creating intricate and complicated parts with precise tolerances, particularly in the early stages of prototyping.

Is it affordable to use rapid injection molding for small-scale production?

Yes. Without the high expenses of conventional mold tooling, it is perfect for small batches, pilot testing, and design validation.

How much time does it take to get the first part?

The first molded item may be provided in as little as 7–10 business days, depending on its complexity.

In which sectors can rapid injection molding offer the most advantages?

It is widely used to expedite product development and testing in the automotive, consumer electronics, medical, and aerospace industries.

When is rapid injection molding most useful?

Ideal for functional prototypes, bridge tooling, low-volume production (hundreds to 10,000 parts).

Ready to bring your product to market faster? Contact UTT Mould today to discover how our rapid injection molding services can accelerate your timeline.