Early-stage prototyping is essential to the ultimate realization of a product idea. Plastic molding is commonly the preferred technique used by engineers, industrial designers, and company founders to transform ideas into concrete, functional models. However, selecting the appropriate molding technique and partner can make or break your development schedule and budget.

You are not alone in considering plastic molding China. The affordable cost, sophisticated tooling skills, and quick turnaround times have made it a global solution in mold-making and prototype production. However, you can avoid expensive setbacks by being aware of what to anticipate and how to proceed.

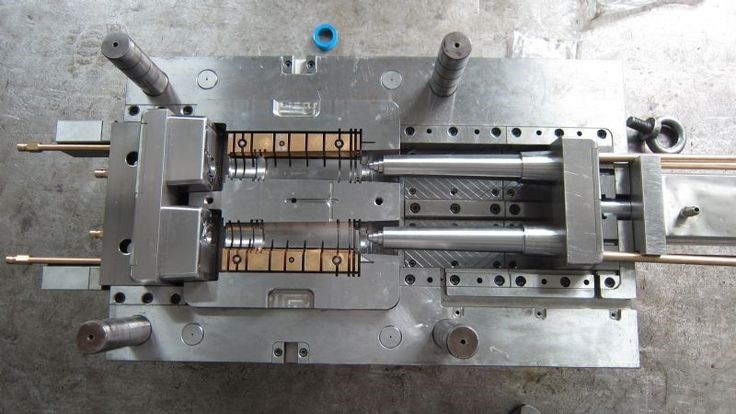

It is important to understand the different molding methods before choosing a plastic molding partner:

● Injection molding is ideal for creating high-precision parts in large volumes. It requires a mold cavity but produces consistent results.

● Blow molding is used for hollow components like bottles or containers.

● Compression molding is better for large, flat, or composite items.

Rapid injection molding is most commonly used for prototyping. It closes the gap between 3D printing and full-scale production by providing a real-world test of form, fit, and function, often using the same materials meant for mass production.

Designers ought to collaborate with a facility that specializes in low-run prototypes as well as high-volume molding. This guarantees that the manufacturer is aware of the necessity of iterative improvement, cost sensitivity, and schedule urgency.

Mold-making is often combined with quick turnaround services by plastic molding companies. Some even provide in-house CNC production before bulk molding starts, which is perfect for producing high-fidelity molds or complementing parts.

A well-designed product for molding considers:

● Draft angles for easy part release

● Wall thickness to prevent warping or sinking

● Material flow for structural strength and even fill

Early collaboration with the mold-making team will help optimize your CAD files to suit moldability, saving you time in revisions later.

Prototypes must resemble the finished product as closely as possible. Inquire about post-processing methods, part tolerances, and surface finish options. Molding companies may work within tight dimensional tolerances and generally offer a wide range of textures, from matte to glossy, when using CNC production to manufacture precise molds.

Prototypes made using plastic molding China can be produced very quickly, but preparation is key to success. The quality and utility of your prototype will be significantly increased by being aware of the molding process, selecting a knowledgeable partner, and designing with production in mind. These preliminary actions are crucial for designers to ensure a seamless transition from sketch to scale.

Why is Plastic Molding in

China a popular choice for prototyping new product designs?

Plastic Molding in China is favored for prototyping

due to its cost-effective services, skilled labor, and access to advanced

manufacturing technologies. Chinese suppliers can produce high-quality

prototype molds quickly, often using CNC production for precision. This

combination helps reduce design-to-market time and allows designers to test

functionality and aesthetics efficiently.

How does CNC production

contribute to the plastic molding prototype process?

CNC production is integral to creating prototype molds

because it offers exceptional accuracy and speed. It allows for custom mold

cavities to be milled directly from CAD files, enabling designers to test form

and function without committing to full-scale injection molding tooling.

What design considerations

should be kept in mind when preparing for plastic molding?

Designers must consider draft angles, uniform wall

thickness, rib placement, and material flow to ensure the part can be

successfully molded. Ignoring these principles can result in warping, sink

marks, or difficult mold release. Collaborating early with a Plastic Molding

China partner can help optimize designs for manufacturability and minimize

costly revisions.

Is it cost-effective to

create prototype molds with Plastic Molding China suppliers?

Yes, it is often more cost-effective to create

prototype molds with suppliers in China due to lower labor and operational

costs, without compromising quality. Many manufacturers also offer hybrid

solutions that combine CNC production with rapid tooling, helping startups and

small businesses test ideas affordably before investing in production-scale

molds.

What are the common

challenges designers face during plastic molding for prototypes?

Common challenges include poor mold design, lack of

draft angles, material incompatibility, and underestimated timelines. Working

with experienced Plastic Molding China manufacturers helps address these issues

early. They often provide DFM (Design for Manufacturability) feedback and use

CNC production to deliver precise parts that closely match your final vision.