Speed is not only advantageous in the startup environment; it is essential for survival. For this reason, IT entrepreneurs all around the United States are relying more and more on Prototyping Tooling to quickly and effectively develop their ambitious ideas. Tooling is now one of the first steps, not the last, as businesses realize, whether they are introducing a game-changing device or perfecting a smart wearable.

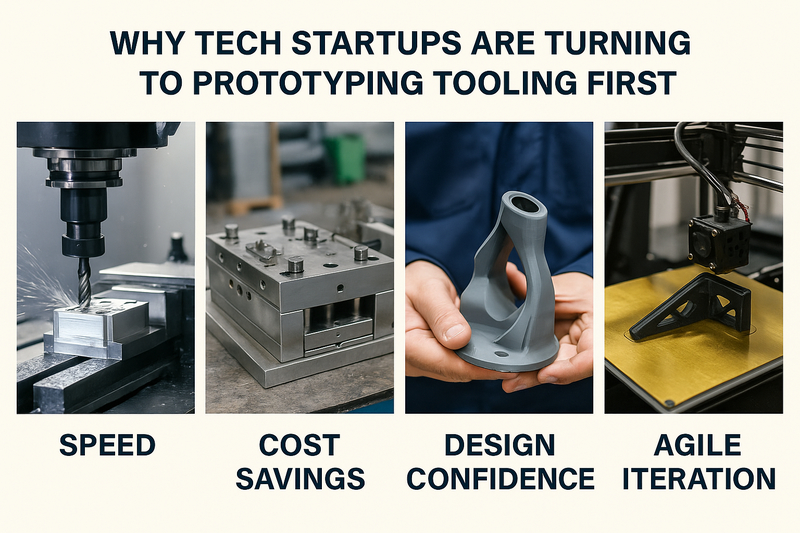

Startups cannot afford to put off testing a concept for months. Prototyping tools can help with that. Developers can produce functional prototypes of their products in a matter of days rather than weeks or months with the use of technologies such as CNC production and 3D printed molds. Instant testing, iterative design, and speedier pivots in response to market feedback are all made possible by this speedy turnaround.

Consider a group of people creating a brand-new fitness monitor. They can employ CNC production to create a unique prototype with precise tolerances and practical functioning instead of making an upfront investment in mass production. The team may then use up-to-date technology to respond to user requests for design changes in a matter of days.

Tech startups typically have tight deadlines and limited funds, unlike major enterprises. These small teams can reduce waste, test their concepts early, and save money by avoiding the need for rework later on with the aid of prototyping tools.

These innovators maintain control, thanks to the regional, tailored services provided by Prototyping Tooling in China. Moreover, businesses may test both form and function before deciding on high-volume production, thanks to CNC capabilities.

What is among the most appealing advantages for new businesses? The adaptability. Prototyping tools enable teams to experiment with materials, finishes, and design options without committing to lengthy production runs, whether they are dealing with complicated composites, plastics, or aluminum. It's ideal for "what-if" situations where creativity and experimentation collide.

Tech startups have high standards for quality, communication, and urgency, and local prototyping tooling firms in the China meet these demands. These partners assist in bridging the gap between concept and commercialization without sacrificing functionality, from early sketches to working beta devices.

Using prototype tools is not only wise, but also necessary in a rapidly evolving tech industry. Using Prototyping Tooling in China and CNC production could be the first and most effective step for businesses hoping to move fast, test bravely, and create wonderfully.

Why

do tech startups prefer Prototyping Tooling China?

Because it offers faster turnaround, localized

support, and better control over early product development.

How

does CNC production fit into prototyping?

CNC production enables precise, small-batch parts for

testing and iteration during the prototyping phase.

Can

prototyping tooling save money?

Yes. It reduces rework, prevents costly design flaws,

and avoids unnecessary bulk production.

Is

prototyping tooling suitable for small teams?

Absolutely. It is ideal for startups that need rapid

testing and agile development without huge upfront investment.

How

long does it take to get a prototype with CNC production?

Depending on complexity, it can take just a few days

to a week.

How does prototyping tooling differ from rapid prototyping?

Rapid tooling creates functional production tools quickly, while rapid prototyping makes non-functional models to test form and fit .

Ready to accelerate development with prototyping tooling? Contact UTT Mould to begin your agile tooling process today!