Every successful product starts with testing, not guesswork. Prototyping tooling, which defines the tools and procedures used to produce early-stage parts or components before full-scale manufacturing, is a common type of test. With this, teams can evaluate design, fit, and functionality in real-world circumstances. Investing in prototyping tooling at the right moment may save time, minimize errors, and save expensive redesigns later. Read this blog till the end to know that moment. Understanding the signals your project is already sending you helps you make the right decision.

Digital designs by themselves are now unable to show how components fit together physically or how materials behave. Prototypes help in identifying design issues early on, when making changes is simpler and less expensive. Investing here fosters smarter decision-making and increases trust across stakeholder, engineering, and design teams.

Even minor design flaws can have an impact on performance as product requirements become more stringent. You can test tolerances, durability, and assembly under real-world circumstances with prototyping tooling. This is especially important for parts that interact with one another.

| Comparison Metric | 3D Printing (SLA/FDM) | Prototyping Tooling | Production Tooling |

|---|---|---|---|

| Ideal Volume | 1 – 20 Parts | 100 – 2,000+ Parts | 50,000+ Parts |

| Material Quality | Simulated Resins | Production-Grade Plastics | Production-Grade Plastics |

| Lead Time | 1 – 3 Days | 2 – 4 Weeks | 8 – 12 Weeks |

| Initial Investment | None (Pay per part) | Low to Medium ($$) | High ($$$$) |

| Functional Testing | Limited (Visual/Fit) | Full (Real Resin Testing) | Full (Mass Validation) |

*Note: Lead times and costs vary based on geometry complexity and material selection.*

When consumers are able to touch and utilize a product, user input is most important. Prototyping tooling allows you to show clients, investors, or test users realistic examples. Their answers frequently have an impact on the final design choices. The gap between concept and expectation is filled with a tangible prototype.

Before investing in expensive production molds, prototyping tools are frequently utilized. It facilitates low-volume production for refining procedures, evaluating market demand, or trial runs. This method preserves quality while lowering risks. At this point, common goals include:

● Examining assembly workflows

● Assessing material selections

● Confirming manufacturing schedules

These findings drive smarter full-scale tooling investments.

Costs can rise dramatically if design modifications are made after production tooling starts. Therefore, investing in prototyping tooling aids in the detection of issues early, when fixes are less expensive. It serves as a safety net, guaranteeing the reliability and manufacturing capacity of your product. This phase safeguards resources and reputation for teams with limited resources or deadlines.

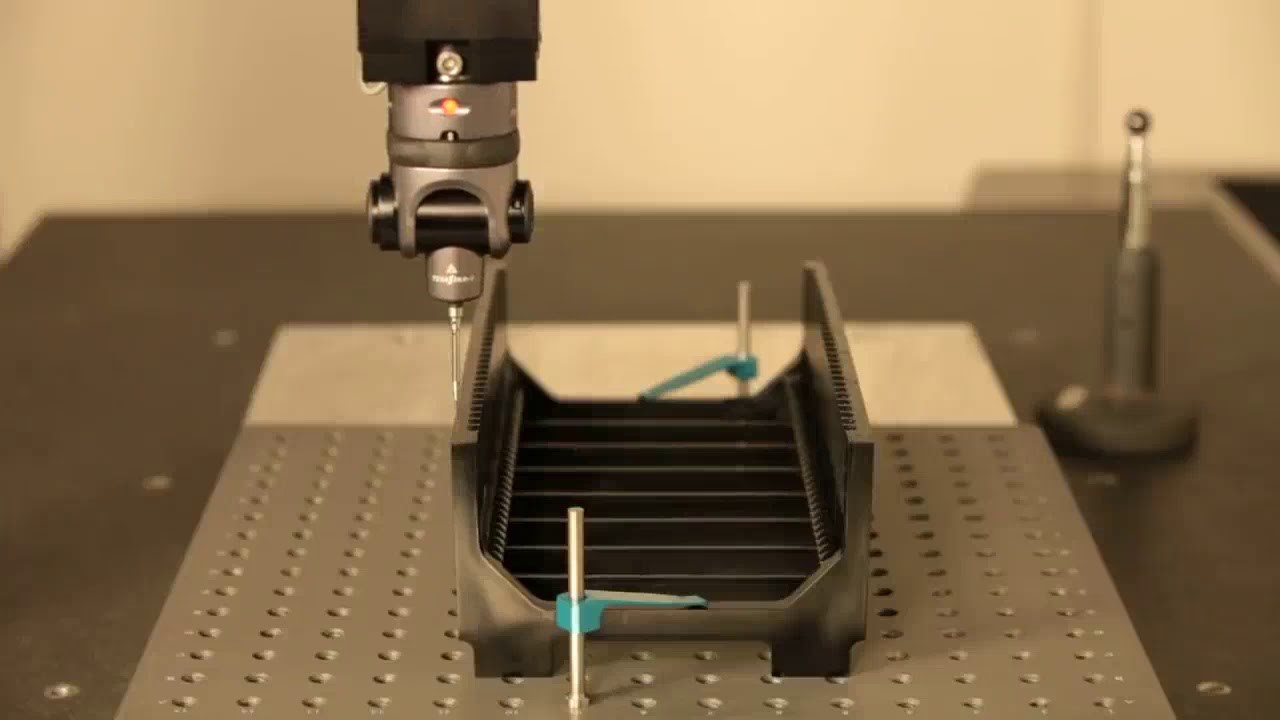

When investing in prototype tooling, timing is crucial. When design choices start to impact cost, performance, or confidence, that's generally the right time. Early testing helps teams move forward with clarity. Businesses that provide dependable solutions suited to growth requirements, such as Uidea Tool Tech Company Limited, assist this crucial stage. When working toward a CNC prototype, a careful approach to prototyping tooling guarantees stronger final products and more seamless production transitions.

What is the ultimate goal of prototyping tooling?

Before committing to scale production or costly tooling investments, prototyping tooling helps develop tangible prototypes to verify design, fit, and functionality.

Can only large manufacturers use prototype tools?

No, startups and small manufacturers also benefit from it, particularly when it comes to early development risk reduction, cost management, and idea validation.

In what ways can the use of prototyping tools lower production risks?

Early detection of design and manufacturing flaws enables adjustments before they become costly issues during full-scale production.

Can we maintain or sustain a low volume of production with prototyping tools?

Yes, this is done often in low quantities or for pre-production runs to establish manufacturing methods and potential market responses.

When should a company go from a prototype to production tooling?

Once performance criteria, quality, and cost expectations meet goals consistently with a prototype, companies can proceed and invest in full production tooling.