The first mold decision often determines whether a product fades or flies.

The choice of tooling has long-term consequences for producers who must balance speed, cost, and accuracy. The familiarity of domestic tooling is reassuring. However, Plastic Mold China silently produces better results in many real manufacturing situations, not by accident, but rather through structure, scale, and discipline.

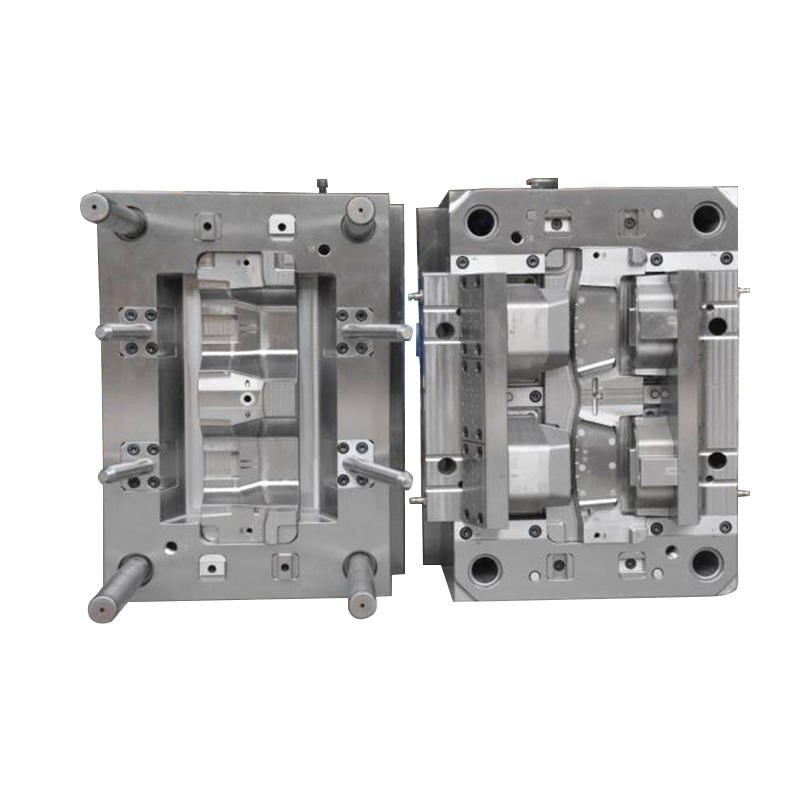

Concentration is the foundation of China's mold manufacturing power. Tooling is the only focus of entire industrial clusters. Testing teams, design engineers, mold manufacturers, and material experts all operate in the same ecosystem. Problems can be resolved in hours rather than weeks, thanks to this density. When demand increases, domestic shops frequently balance tooling with other fabrication tasks, which can cause delays.

Plastic Mold China clearly has an advantage for projects that call for parallel constructions or numerous mold iterations. No capacity is borrowed. It is integrated.

It is a common misperception that foreign tooling compromises precision in favor of cost. In reality, mold factories make significant investments in surface control, cavity balance testing, and high tolerance machining. These powers are not unique. They are anticipated.

Domestic tooling can achieve this precision, but frequently at a greater unit cost due to workforce structure and lower volume productivity. Plastic Mold China often provides a better balance when budgets are restricted and standards are strict.

Product development rarely moves in a straight line. Rapid prototyping services are essential in this situation. Prototyping is frequently included directly into tooling workflows by China mold partners. While momentum is still high, changes are made to the material behavior, wall thickness, or gate design.

Handoffs and delays may result from the reliance of domestic tooling on external prototyping vendors. Integrated prototyping significantly reduces the learning curve when time is of the essence, particularly in consumer or electronics sectors.

Localized, low-volume production benefits significantly from domestic tooling. However, the economics change as volume increases. Plastic Mold China is made to be replicated on a large scale. The original design incorporates maintenance cycles, cavity duplication, and tool life planning.

This foresight lowers downstream risk for brands planning extended production runs or worldwide debuts. The mold is not only made. It is prepared to endure.

Clarity was one of the previous criticisms of outsourced tooling. That difference has shrunk considerably. The top China mold suppliers of today use bilingual engineering teams, thorough documentation, and organized approval processes. Language is no longer the topic of discussion. It has to do with expectations.

| Key Feature | Domestic Tooling Solutions | Plastic Mold China (UTtmould) |

|---|---|---|

| Tooling Cost | High (Labor & Overhead) | 30-50% More Cost-Effective |

| Lead Times | Standard (Capacity Limited) | Accelerated (Large Scale Capacity) |

| Production Scale | Optimized for Low Volume | Seamless Mass Production Scaling |

| Technical Talent | Local Expertise | World-Class Engineering Specialized in Export Standards |

| QA Standards | High (Local Regulations) | Global Compliance (ISO/IATF 16949 Standards) |

Plastic Mold China frequently surpasses local tooling with silent confidence when projects require speed, iteration, and scale without raising costs. The most astute manufacturers understand when global competency triumphs and when familiarity is helpful.

When

does Plastic Mold China make more sense than domestic tooling?

Plastic Mold China excels when projects call for

intricate molds, frequent design modifications, or medium to high production

volumes where consistency and cost control are more important than proximity.

Is

quality control reliable with China mold manufacturers?

Established mold makers follow strict inspection

protocols, detailed sampling processes, and documented approvals, offering

quality levels comparable to leading domestic tooling shops.

How

do Rapid Prototyping Services improve mold outcomes?

Rapid Prototyping Services allow early testing of

form, fit, and function, enabling faster corrections before full tooling

commitment, reducing costly rework later in production.

Can

Plastic Mold China support long term production runs?

Yes. Many molds are engineered for extended lifecycle

use, with maintenance planning and cavity scalability built into the original

tooling strategy.

Ready to leverage the unparalleled advantages of Plastic Mold China? Contact UTtmould today for a free consultation and discover how we can deliver high-quality, cost-effective tooling for your next project.