The fastest products to win are rarely the

loudest. They are the ones that arrive prepared.

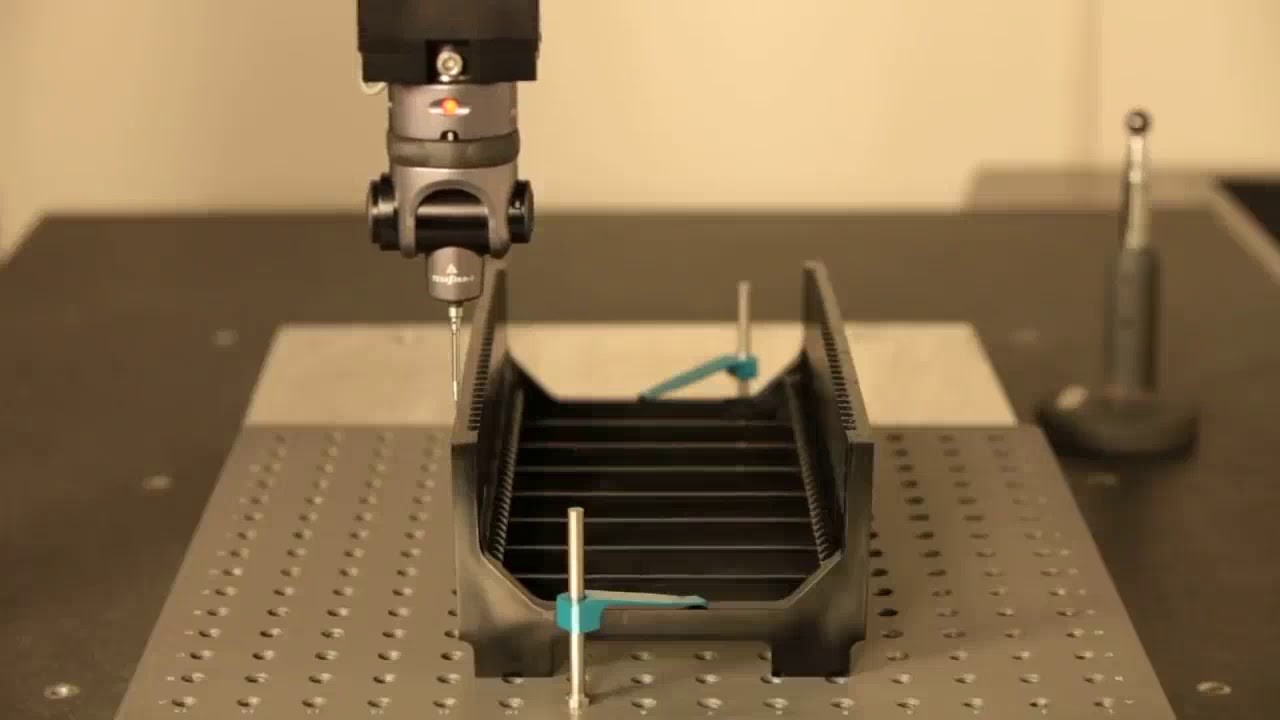

Ideas are everywhere in the short launch cycles of today. Execution is rare. Prototyping molding silently determines whether products confidently reach the market and which

fail due to unforeseen design elements. It's not a quick fix. It is a tool for

thinking that emphasizes accuracy, timeliness, and clarity.

Product launches are more likely to fail due to late findings than poor ideas. A design that appeared flawless on screen can behave otherwise when molded, assembled, or handled. Prototyping Molding moves those discoveries forward, when change is still affordable.

Teams see how materials react, tolerances behave, and users engage with the product rather than speculating. Friction spots that are never seen in drawings are revealed by early molded prototypes. Instead of being guesswork, decisions become informed.

Speed is crucial, but blind speed is more expensive. Molding reduces launch schedules by eliminating uncertainty. Teams may expedite approvals and reduce changes when they test form, fit, and function using production-like procedures.

This strategy is particularly beneficial when collaborating with international industrial partners. A wide range of materials, and cost control, many brands rely on Prototype China services for quick tooling. Geographical location is not the benefit. It is early, large-scale repetition.

A commitment is made during a product launch. Keeping that commitment is aided by prototyping molding. Surface finishes, assembly logic, part strength, and usability can be refined before marketing ever begins.

Companies respond to prototype feedback prior to launch rather than responding to customer comments after release. As a result, launches are quieter but produce better results. Fewer returns. Less changes. Greater confidence.

The true cost savings from prototyping molding are not very noticeable. Fewer modifications to the tooling. Fewer delays in production. Less post-launch emergency fixes.

When deadlines are tight and stakes are high, teams can prevent expensive redesigns by confirming molds and materials early. This discipline preserves margins without requiring later concessions.

Confidence affects internal teams, distributors, and investors. Choices are made faster and with greater clarity when a product is supported by validated prototypes. Prototyping molding offers evidence rather than assurances.

Scale is accelerated by that proof. It doesn't feel dangerous, but rather expected when production starts.

A successful launch is rarely dramatic. It feels calm. Prototyping Molding creates that calm by replacing last minute panic with early certainty. Products arrive not just faster, but ready to stay.

How does Prototyping Molding improve

launch speed without increasing risk?

Prototyping Molding exposes design and material issues

early, when changes are easier. This reduces late stage revisions, shortens

approval cycles, and helps teams move forward with confidence rather than

assumptions.

Is Prototyping Molding only useful for

complex products?

No. Even simple products benefit because small issues

often scale into larger problems. Prototyping Molding validates real world

performance regardless of design complexity or industry.

Why do companies source Prototype

China services for prototyping?

Prototype China providers offer fast turnaround,

tooling experience, and material access. This combination allows brands to test

multiple iterations efficiently before committing to full production.

Can Prototyping Molding reduce post

launch product changes?

Yes. Testing molded prototypes before launch uncovers

usability, durability, and assembly concerns early. This prevents reactive

fixes after release and protects brand credibility.

Ideally after initial design validation but before final tooling. Introducing Prototyping Molding early enough allows meaningful changes while timelines and budgets remain flexible.

Don't let your competitors beat you to market. Leverage the power of speed and precision. Contact UTtmould today to discuss how our prototyping molding solutions can give your next product launch a decisive competitive advantage.