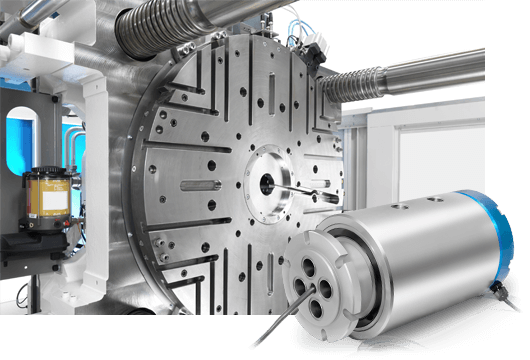

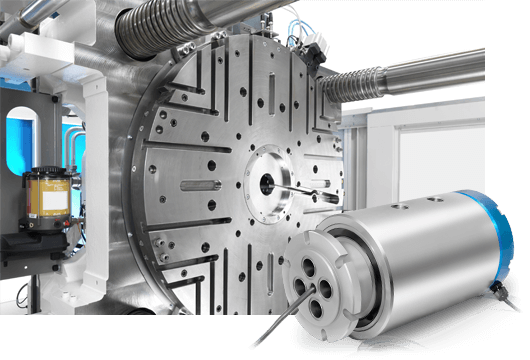

Two-shot moulding is a procedure in which two materials are 'over formed' in one cycle of the moulding process and this procedure requires injection moulding machines typically made for the purpose. The word 'shot' alludes to the volume of material infused into the mould cavity. In two-shot moulding, an underlying part is formed and when it is done a second part is embedded which will frame the rest of the piece of the mould.

For the

two-shot moulding procedure to work the two sections must be chemically similar otherwise holding won't occur. This moulding method can be utilized to bond a piece of hard material with a delicate material. The procedure includes the making of two parts in a two cavity mould. It can enormously improve the products’ appeal of appearance, color, feel and so forth. Two-shot moulding offers a wide range of design possibilities.

A material compatibility chart is considered and consulted before starting the moulding process in order to check which polymers will join together and which polymers are not compatible with each other. It also eliminates the risk of contamination, which poses a problem while using two different moulds. The two-shot moulding process also creates a bond stronger than the same part being produced in two separate moulding processes.

Applications of Two-Shot Injection Molding:

The moulding is a plastic molding process ideal for making multi-color, multi-material, and complex plastic products, especially in large-volume production lines. It is used to make several products in a variety of industries including medical, appliance, consumer, appliance, lawn and garden, agriculture along with a significant experience in automotive parts.

From as mini as consumer goods to giant construction requirements, two-shot molded components are utilized in almost all the industrial sectors, but are most widely found in following applications:

• Rigid substrates with soft grips

• Surface descriptions or identifications

• Vibration or acoustic dampening

• Moveable segments or components

• Multi-color or multi-material components

• A green and black molded automotive structural pillar

• A grey and black two-shot molded automotive component that combines rigid and flexible materials

• A beige and black two-shot molded plastic part with Christmas tree fasteners

Benefits:

Complex Moulding: Two-shot molding makes the creation of complex design moulds that incorporate multiple materials for functionality that is impossible to achieve through other processes.

Improved Efficiency: This process lets two or more components to be perfectly moulded with a single tool, reducing the number of labors needed to produce the parts and also removing the need to weld and join two separately moulded components.

Part Consolidation: Two-shot moulding lowers the number of components in a finished assembly, saving an average of $40K in development, engineering, and validation costs associated with each additional part.

Improved Quality: The process is carried out using only a single tool, allowing lower tolerances than other processes; a high level of repeatability is there while maintaining accuracy, and reduced waste materials.

If compared to other methods of moulding, two-shot is ultimately a more cost-efficient way to produce and assemble multiple components.