Rapid Injection Molding: Cut Lead Times from Weeks to Days | Uttmould

Rapid Injection Molding is a manufacturing process that uses simplified mold designs and automated CNC machining to produce functional plastic parts in 2–4 weeks. Compared to traditional molding (10+ weeks), it uses aluminum or pre-hardened steel tools to drastically reduce costs and time-to-market.

When the deadline is approaching, even the finest product ideas may become stressful. Waiting weeks for tools or parts is just not an option in such situations. This is where rapid injection molding can be a game-changer. It is a manufacturing technique that produces molded parts far more quickly than traditional methods by using streamlined procedures and simpler tooling. Faster tooling, quicker approvals, and earlier production runs let teams move forward without delay. Continue reading for a detailed explanation of how this method saves time at each and every step.

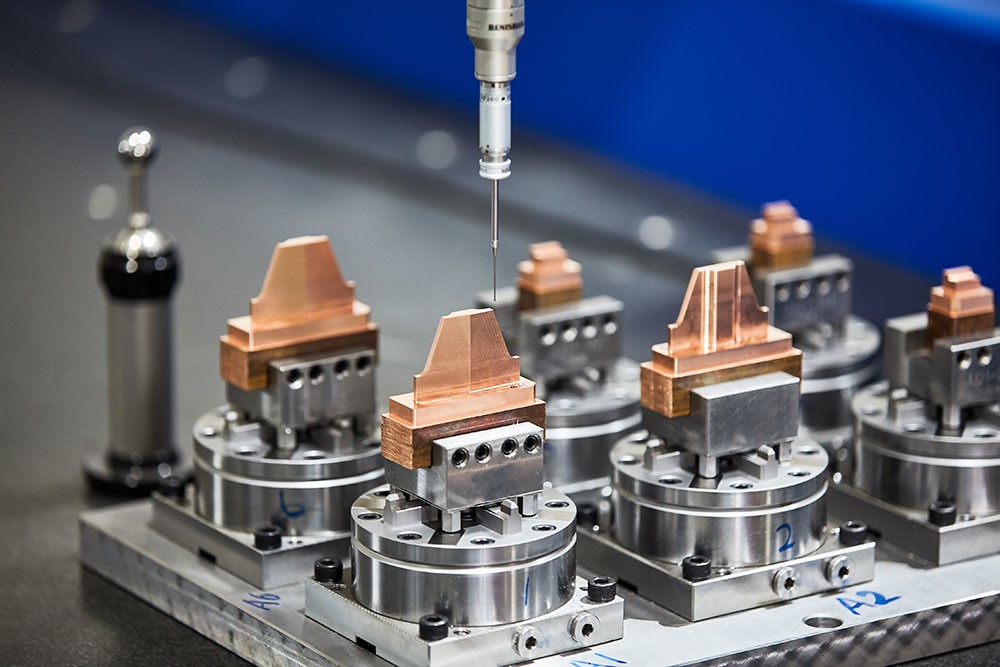

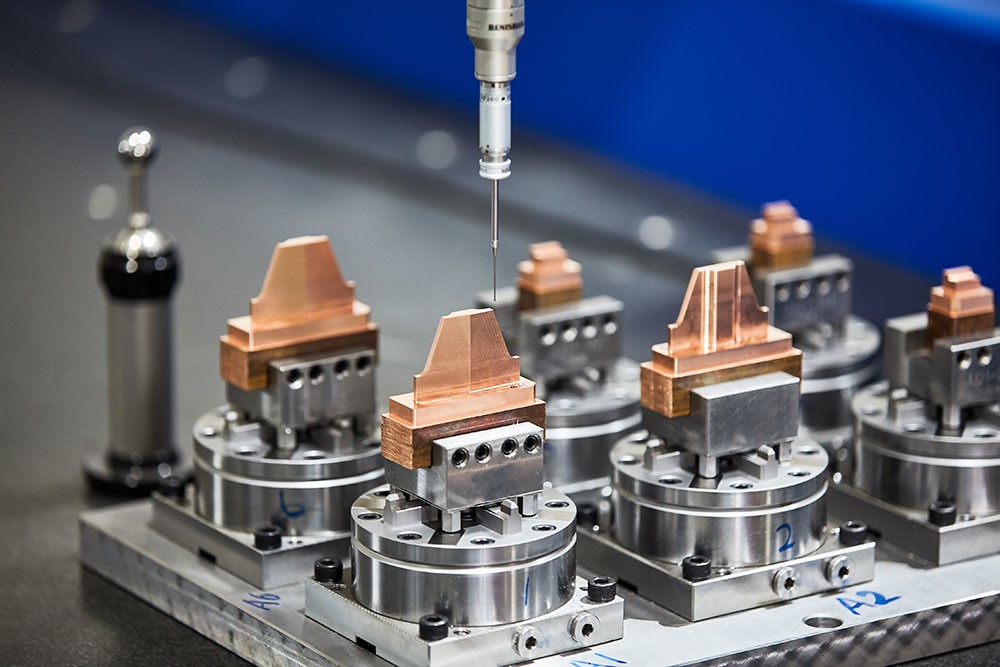

Quicker Tooling Without Needless Delays

Traditional mold manufacturing sometimes takes weeks because of intricate tool designs and prolonged machining schedules. Practical tools designed for speed are the main emphasis of rapid injection molding. Simplified mold designs nonetheless satisfy dimensions and functional criteria. In order to prevent later adjustments, skilled engineers optimize tool paths and make judgments early. As a result, the mold is ready far sooner, enabling production to start while competitors are still awaiting the completion of tooling.

Early Validation of Designs Saves Weeks

One important reason projects slow down is the late identification of design flaws. Early in the development cycle, businesses can generate functioning parts with rapid injection molding. Fit, strength, and practical application can all be verified for these components. It is easier and faster to implement changes when issues arise early. This cuts down on repeating design cycles and avoids lengthy delays that frequently occur when problems are discovered after a significant tooling investment.

Brief Production Runs That Need Actual Requirements

Not every project requires hundreds of thousands of pieces right away. In order to meet actual demand, rapid injection molding enables low to medium-volume production. This strategy avoids waiting for huge batch approvals or extra setup time. It is especially effective for trial runs, market testing, and connecting production before expanding. With viable pieces in hand, teams can plan the following stages with confidence.

Reduce Idle Time with Parallel Processes

When activities are completed concurrently rather than sequentially, speed increases. With quick injection molding, design evaluations, material selection, and tooling preparation typically proceed simultaneously. Between phases, this synchronization reduces idle time. Moreover, clear communication between engineering and production teams keeps decisions moving.

|

Feature

|

Traditional Molding

|

Rapid Injection Molding

|

|

Lead Time

|

6 - 8 Weeks

|

2 - 4 Weeks

|

|

Tooling Material

|

Hardened Steel

|

Aluminum / P20 Steel

|

|

Cost

|

High (CapEx)

|

Cost-Effective

|

Reliable Quality Without Slowing Progress

Speed only matters if quality stays consistent. Rapid injection molding uses proven materials and regulated procedures to guarantee constant quality. Instead of taking experimental shortcuts, parts are made using proven molding procedures. This balance guarantees quicker delivery without sacrificing dependability or performance. When parts arrive ready for use, teams minimize delays caused by rework or rejection, keeping the entire project on schedule.

The bottom line

Quick lead times can determine a product's success or failure. Thus, rapid injection molding gives organizations the confidence to go forward by cutting down on tooling time, facilitating early testing, and supporting realistic production quantities. If you value speed, accuracy, and clear communication, make sure to work with the right manufacturing partner. Every project benefits from the experience, discipline, and reliable outcomes that Uidea Tool Tech Company Limited brings to the table. Selecting a dedicated molding expert might be crucial for businesses weighing international options such as 3D printing in China.

FAQs

How quickly can rapid injection molding produce parts?

Tooling can be completed in a matter of days, depending on complexity, and molded parts can be provided soon after material confirmation and first approval.

Can end-use parts be created with rapid injection molding?

Yes, it creates durable, useful parts that are appropriate for practical uses rather than only conceptual or visual prototypes.

Which sectors frequently use fast injection molding?

Consumer items, automobiles, medical devices, and electronics typically use it for testing, pilot production, and early market introductions.

Do greater expenses result from quicker production?

Not always. By reducing redesigns, delays, and lengthy development cycles, shorter lead times frequently result in cheaper project costs overall.

What makes Uidea Tool Tech Company Limited the best option?

They allow clients to acquire precise parts quickly and without needless complexities by combining practical engineering, clear communication, and constant quality.

Ready to accelerate your project? Upload your CAD file today for a free DFM review and a quote in 24 hours.