Have you ever wondered how thousands of car

parts come out looking identical? Dashboard panels and under-the-hood housings

are only two of the hundreds of plastic parts used in modern cars. According to

studies, plastics now make up about half of a vehicle's volume. One fundamental

process is responsible for this accuracy and constancy. We are talking about an automotive injection mold. Let's learn how this process works and why it is

important.

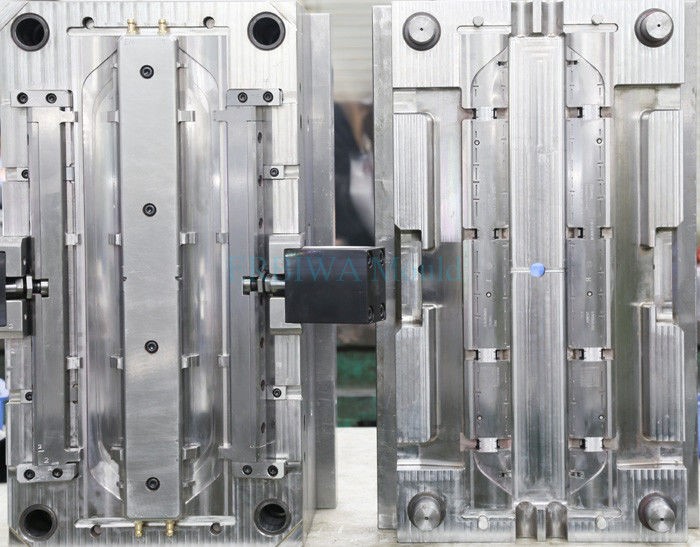

A specialized metal instrument

called an automotive injection mold is used to precisely shape molten plastic into car parts. After

being heated and injected into the mold, the plastic is cooled and released as

a completed part. This technique allows manufacturers to create the same part

again with minimal modifications.

Tight tolerances, which require

parts to conform within small measurement limits, are used in the construction

of cars. So even a small change might have an impact on performance or safety. Automotive injection molding reliably produces this accuracy. It guarantees

that components line up correctly with safety systems, electronics, and metal

structures, reducing the chances of errors once the car is on the road and

minimizing assembly problems on manufacturing lines.

Production of automobiles

depends on speed without compromising quality. The purpose of injection molds

is to manage large-scale production. An identical part can be quickly

replicated thousands of times after the mold is made. Manufacturers are able to

meet demand while keeping costs under control because of this efficiency.

Additionally, it guarantees the consistency of replacement parts, which is

crucial for maintenance and repairs throughout the course of a vehicle's

lifetime.

Certain components require

impact strength or flexibility, while others require heat resistance. ABS,

polypropylene, and nylon are just a few of the many materials that automotive

injection molding can handle. The part's intended purpose determines the material

selection.

Injection molding makes it

possible to create intricate shapes that are challenging to do using

conventional techniques. This promotes contemporary vehicle design without

sacrificing security. Airbag housings, clips, and brackets are examples of

parts that need to be strong and precisely shaped. Molds guarantee that these

components function as planned in practical applications.

Injection molding is not an

independent technique. It enhances operations such as metal shaping and

stamping. Plastic parts frequently fasten straight to metal panels or frames.

This coordination guarantees a well-balanced construction that combines weight

economy and strength.

Automotive injection mold technology guarantees accuracy, facilitates mass production, and

allows modern design flexibility in vehicle production. It helps cars meet

performance and safety standards by creating dependable plastic parts.

Manufacturers may produce well-balanced, superior automobiles that satisfy

international requirements when they incorporate additional processes, such as sheet metal fabrication in

China.

Why is injection molding so

popular in the automobile industry?

It is perfect for creating

large quantities of identical automobile components because it offers speed,

accuracy, and consistency.

What kinds of car parts are

manufactured with injection molds?

Dashboards, interior trimmings,

clips, housings, and under-the-hood components that need to be precise in size

and durability are examples of common parts.

Are injection-molded

components robust enough for vehicles?

Yes. Strength, heat resistance,

and impact performance are features of automotive-grade polymers that make them

appropriate for use in automobiles.

What is the lifespan of an

automotive injection mold?

Over the course of its

operating life, a high-quality mold may create hundreds of thousands of parts

with regular maintenance.

Does injection molding make

cars lighter?

Yes. Molded plastic components

can be used in place of metal, which reduces weight while enhancing vehicle

performance and fuel economy.

Ready to launch your next vehicle component? Contact UTTMOULD today for high-precision automotive injection mold solutions that meet global safety and quality standards.