Did you know that the design phase locks in around 70% of the expenses associated with product development? Even the smallest defect during the design may become a costly issue once manufacturing begins. For this reason, prototyping molding is a very wise choice. Before committing to full-scale production, it allows you to view, touch, and test your product. With this, you can identify and correct errors early on, whether you're making consumer electronics or car parts.

Designs that seem flawless on paper often have defects when they are put into practical form. Before mass production, prototyping molds may help you find problems like weak areas, misalignments, or fit concerns. This allows you to fix issues early and avoid expensive rework later.

You may test the behavior of your product in real-world settings using a prototype mold. Using real materials, you may assess strength, flexibility, and usefulness, guaranteeing that your product functions properly.

Prototyping really shortens your whole development cycle, despite the fact that it could appear like an additional step. Early testing helps you get closer to market launch by avoiding many redesigns later.

It is significantly more costly to find a design defect after production has begun than to address it during the prototype phase. Early design refinement helps you prevent wasting labor hours, materials, and tooling. Because they save costly errors, prototyping molds pay for themselves.

Small errors might lead to major problems when parts must fit together precisely. Prototyping allows you to verify that every component works together as a whole. It guarantees seamless assembly and excellent final products.

Engineers, designers, and decision-makers may communicate more effectively when they see an actual, physical model. It eliminates uncertainty and keeps everyone focused on the same goal. Thus, a prototype mold serves as a bridge between manufacturing and creativity.

A functional prototype is strong evidence. It demonstrates to prospective customers or investors that your design is practical and real rather than just theoretical. This assurance often facilitates quicker project approvals or funding.

Every successful product starts with testing, and testing starts with a prototype. Prototyping molding lets you identify design defects before they become expensive production issues. It's a smart, practical, and very efficient approach to refining your design early on. Moreover, working with businesses that provide rapid prototyping services guarantees accuracy, quicker turnaround times, and expert advice throughout the development phase.

What does prototyping molding mean?

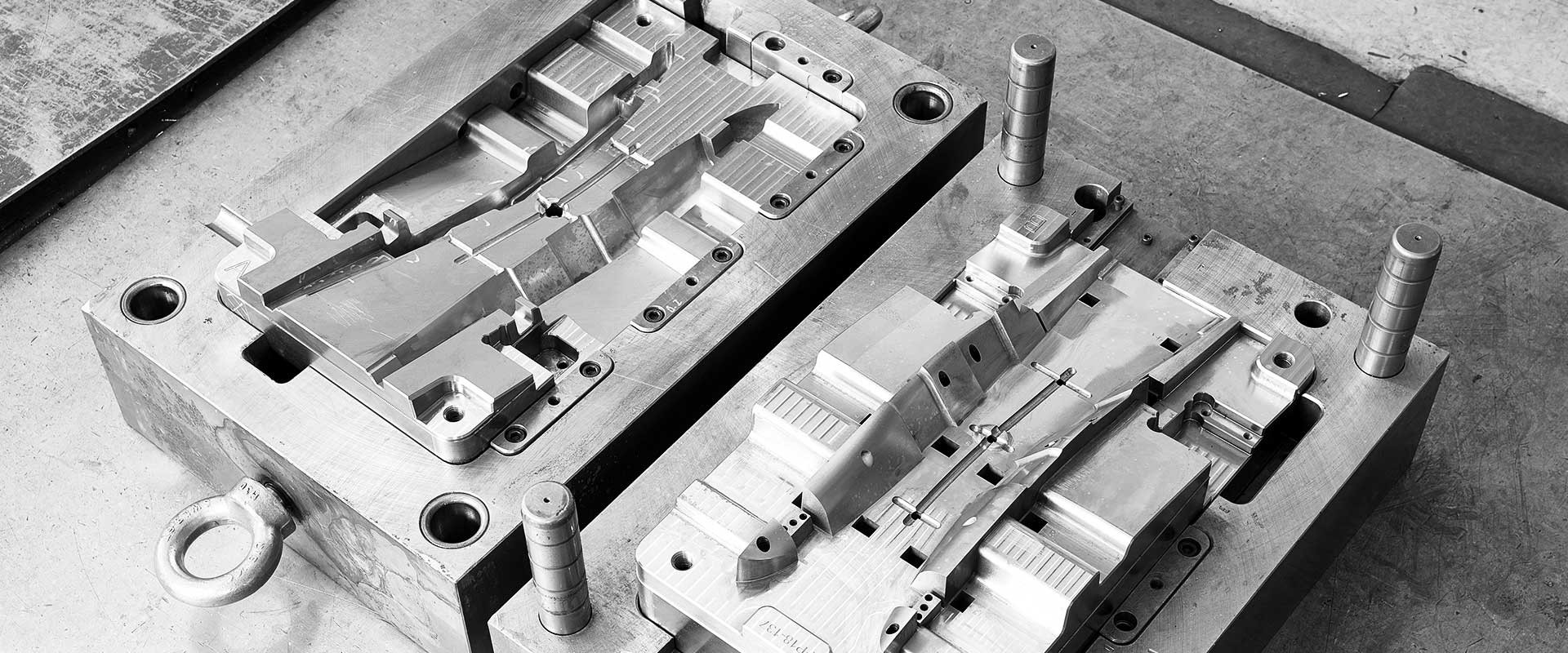

Before mass manufacturing starts, prototype parts are manufactured using a temporary mold for testing through this process.

In what ways does prototyping molding save cost?

It reduces waste, rework, and costly tooling modifications later in production by identifying design and functional problems early.

What components go into making prototype molds?

For quick and economical molding experiments, aluminum, soft steel, and sometimes plastic resins are used.

How much time does it take to create a prototype mold?

It may take a few days to a few weeks, depending on complexity, which is far quicker than full-scale tooling.

Who benefits the most from molding prototypes?

Early testing and validation are beneficial to engineers, designers, and manufacturers in sectors including consumer products, electronics, and automobiles.