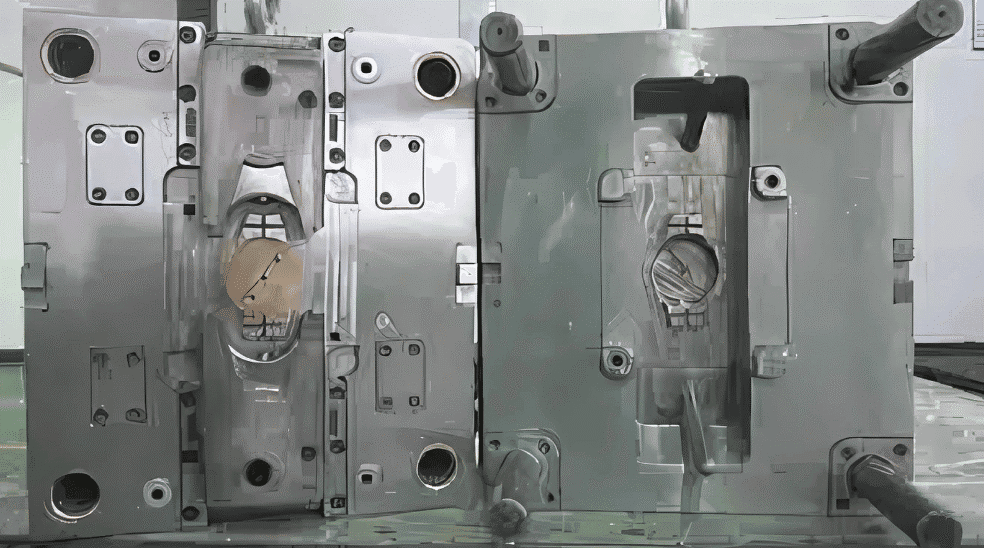

An entire production line can be disrupted by a single mold flaw. Understanding plastic molding flaws is, therefore, essential for producers everywhere. The process of precisely shaping raw plastic into forms used in consumer goods, electronics, automotive, and healthcare industries is known as plastic molding.

Customer satisfaction, product safety, and durability are all directly impacted by the caliber of these molds. This is why selecting the correct supplier is essential if you're sourcing plastic molds in China to prevent expensive problems. Read till the end, as this blog will break down typical mold flaws and how to avoid them.

Poorly designed cooling systems or mold surfaces frequently result in scratches, sink marks, and rough finishes. While these flaws may look minor, they harm the product's structure and reduce its visual appeal. They can be prevented with high-quality polishing, careful temperature management, and the use of long-lasting mold materials. Surface consistency is also guaranteed by routine inspection and preventative maintenance.

Plastic components can twist out of shape due to warping, which happens when they cool unevenly. This flaw wastes valuable materials in addition to decreasing product reliability. To eliminate this defect, manufacturers need to carefully regulate injection pressure and ensure consistent cooling. Distortion in final products can be greatly decreased by working with suppliers who are knowledgeable in cooling design and material behavior.

When molten plastic does not entirely fill the mold cavity, gaps or pieces remain, resulting in a short shot. Inadequate material flow, low injection pressure, or poor venting are frequently the causes of this. The utilization of premium raw materials, steady injection speed, and appropriate venting design are necessary to prevent short shots.

Incorrect alignment, worn-out molds, or inadequate clamping force are typically the causes of Flashing. It is extra plastic that seeps out of the mold cavity and forms undesired, thin layers around a product's edges. Maintaining molds on a regular basis, carefully inspecting alignment, and using the proper injection pressure are all necessary to prevent flashing. Experienced specialists can promptly identify these problems before they become serious flaws.

Discolored stripes known as burn marks are brought on by trapped air or overheating within the mold. They negatively impact the final product's appearance and weaken it. Manufacturers must monitor material temperature, minimize excessive injection speeds, and make sure sufficient venting is in place to avoid this. Most burn mark problems can be avoided before they arise with a well-designed mold that has effective air escape pathways.

Molding flaws can result in material waste, increased expenses, and unhappy customers. Businesses may consistently produce excellent outcomes by identifying these problems early on and collaborating with experienced suppliers. Careful supplier selection and quality inspections are crucial if you're sourcing plastic mold in China. Many businesses also use CNC prototype solutions along with it for increased testing and prototyping accuracy. A trustworthy partner helps you avoid setbacks by guaranteeing accuracy, robustness, and production efficiency.

Which industries in China use plastic molds the most?

Due to its cost-effectiveness, large production capacity, and extensive material availability for a variety of applications, it is widely used in industries like automotive, medical devices, packaging, electronics, and home goods.

How can I find a trustworthy supplier of plastic molds?

Look for vendors who have a track record of success, up-to-date machinery, strict quality control, and open lines of communication. Asking for references and prototypes can help you pick a partner who can create dependable and consistent molds.

What leads to the majority of plastic molding flaws?

Poor cooling systems, incorrect injection parameters, subpar raw materials, or worn-out molds are the usual causes of defects.

Can production costs increase due to mold defects?

Yes, flaws frequently result in product recalls, extended production schedules, and material waste. Long-term cost savings and increased efficiency are guaranteed when these problems are avoided during the design and maintenance phases.

Does mold require preventive maintenance?

Yes. Preventive maintenance guarantees constant product quality, decreases unplanned breakdowns, and increases the lifespan of products.