First impressions are crucial when launching a product; they are not merely significant. A product's first look and feel may make or break its reputation, whether it's a high-precision car part, a stylish phone case, or a household appliance. Production tooling is the driving force behind that first wow factor.

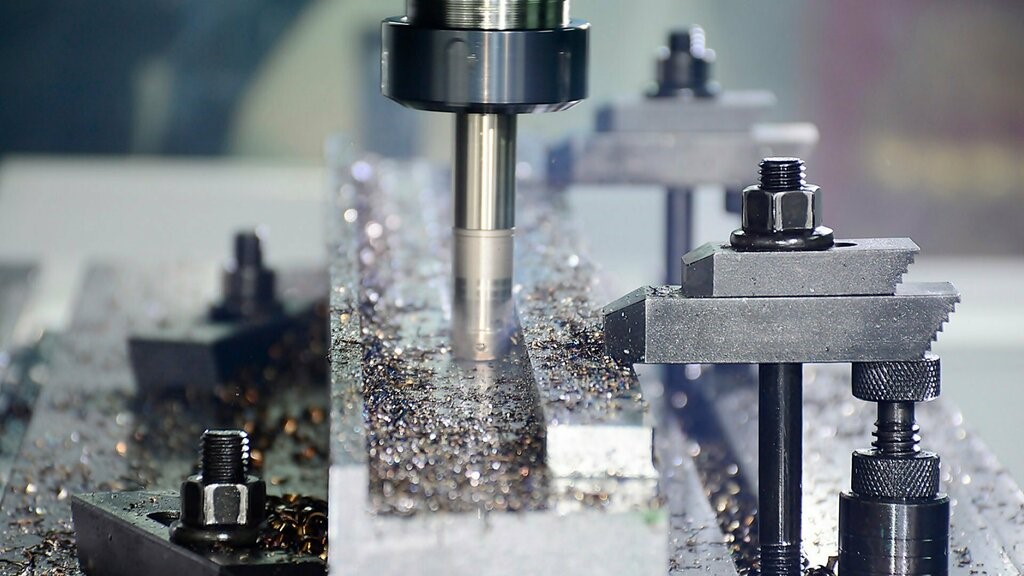

The process of making customized tools, molds, dies, or fixtures that mold and form your product during manufacturing is known as production tooling. Even the slightest deviation in tooling might result in flaws, irregularities, or subpar finishes that immediately drive away buyers. A well-designed tool guarantees that each unit is the same in terms of shape, quality, and accuracy, giving your product a high-end and reliable feel right from the beginning.

Speed to market is essential in the fast-paced business of today. However, rushing without careful tooling might have fatal results. Fast turnaround and excellent quality are achieved by brands who invest in professional tooling, making sure they don't compromise on either.

Long-term benefits outweigh the initial cost of setting up high-quality production tools. High-quality tools reduce waste, rework, and total production costs because they last longer, require fewer modifications, and yield consistent results.

Although they may never hear the term "production tooling," consumers will be able to observe its effects. A faultless, reliable, and polished product subtly conveys that your company cherishes excellence. This promotes word-of-mouth marketing, fosters repeat business, and increases trust long before you launch an advertising campaign.

To put it briefly, production tooling is a strategic investment in the initial perception of your product and the long-term reputation of your brand, not just a manufacturing phase.

Working with a reputable Production Tooling supplier might make all the difference if you want your product to be noticed right away. Additionally, Rapid Prototyping Services can assist you in refining your product before committing to full-scale tooling if you want to validate designs prior to mass production.

How

does production tooling affect a product’s first impression?

Production tooling determines the shape, texture, and

overall finish of your product. High-quality tooling ensures every detail is

precise, making your product visually appealing and consistent, which

significantly impacts customer perception.

What

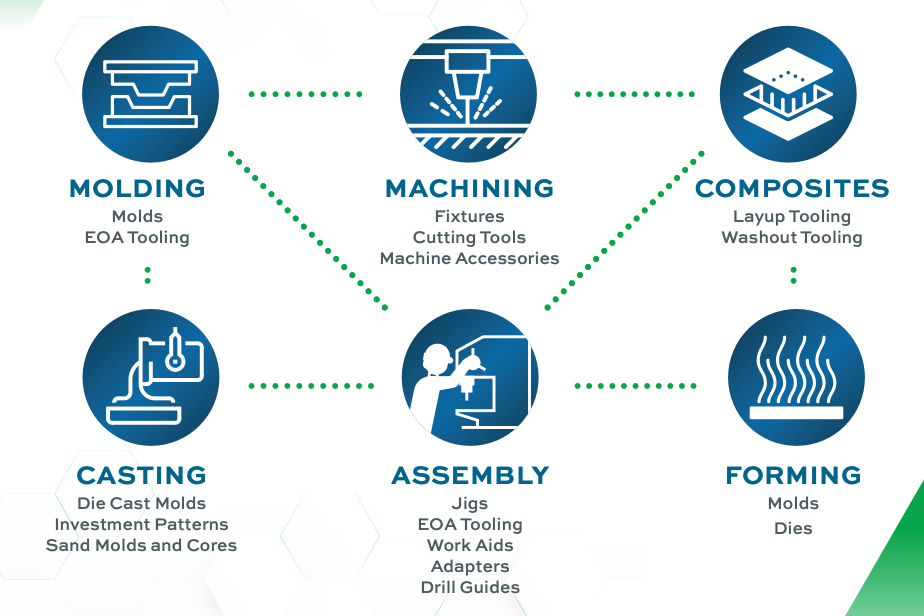

industries benefit most from production tooling?

Almost every manufacturing sector relies on production

tooling: automotive, electronics, medical devices, consumer goods, and

packaging. Consistent quality and precision in tooling benefit any industry

aiming for large-scale, high-quality production.

Why

is precision so important in production tooling?

Even tiny deviations in tooling can cause defects,

poor assembly fit, or surface imperfections. Precision tooling ensures that

each product matches design specifications exactly, improving both function and

appearance.

How

does rapid prototyping relate to production tooling?

Rapid prototyping allows manufacturers to test and

refine product designs before investing in full-scale tooling. This helps avoid

costly errors, speeds up development, and ensures the tooling process produces

the desired results.

Is

high-quality tooling worth the investment?

Yes. While the initial setup cost may be higher,

quality tooling lasts longer, reduces manufacturing defects, minimizes waste,

and ensures consistent product quality, saving time and money in the long term.

Ready to elevate your product’s first impression? Contact UTT Mould for precision production tooling that delivers consistency, reliability, and quality.