Every new product introduction is a race against time, and the companies that can move the fastest without sacrificing quality usually win. Imagine preponing your launch schedule by months without sacrificing accuracy. That is the true power of rapid injection molding. The key is whether your company is ready to use it as a game-changer. Let's examine how this manufacturing method can give you a noticeable advantage and totally transform your product launch plan.

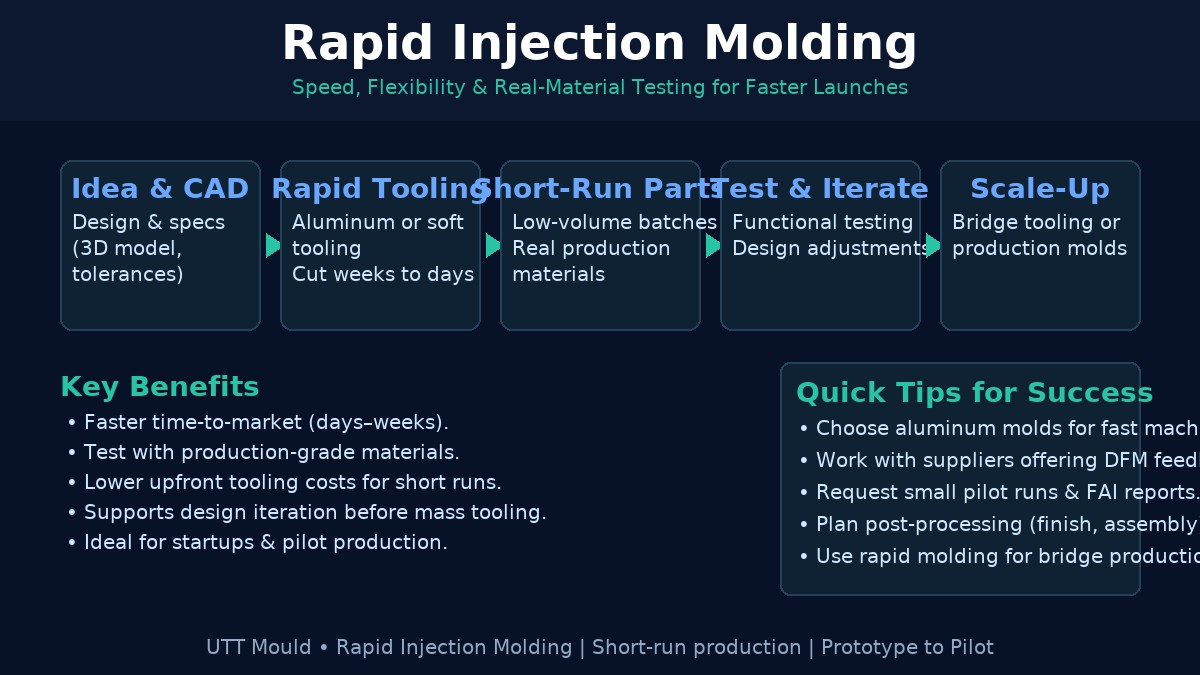

When it comes to product creation, timing is critical. Rapid injection molding enables you to test designs earlier and make important decisions more quickly by reducing the time between concept and physical product. Whether your product hits the market at the right time or too late is frequently determined by this speed.

Even the finest product concepts change after the initial prototype. Changing a design and creating new iterations doesn't cause the project to slow while using rapid injection molding. You can make changes till you are satisfied and are not limited to a single version with this flexibility.

It's risky to launch a product without first validating it. Fast functional part creation, real-world testing, and performance confirmation are all made possible by rapid injection molding. Early defect detection reduces expensive risks prior to full production scaling.

Faster manufacturing does not automatically translate into higher costs as usually assumed. Compared to traditional molds that need a significant initial investment, rapid injection molding produces short-run items at a cost-effective rate. Real value is added by this balance between cost and quality.

Launching a new product often depends on having faith in its usability, durability, and design. Making decisions gets easier when you are holding a part that reflects the quality of the finished product. Stronger launches are fueled by rapid injection molding, which gives teams evidence rather than conjecture.

Waiting too long to test, validate, and launch might be the difference between success and missed opportunities in today's competitive landscape. That timescale is altered by rapid injection molding, which allows companies to develop swiftly with fewer expenses and risks. It creates the conditions for products to arrive on the market quickly and with assurance by introducing agility, confidence, and clarity into the launch process. It could be time to combine it with contemporary solutions like CNC Machining Services if you are serious about changing your approach.

What

makes rapid injection molding different from traditional molding?

Traditional molding is built for large-volume

production with longer lead times, while rapid injection molding focuses on

producing small batches quickly. It enables faster testing and adjustments

without the heavy costs of traditional molds.

Can

rapid injection molding handle complex designs?

Yes, it can produce intricate shapes with remarkable

accuracy. While certain designs may require engineering tweaks, this process

allows businesses to explore complexity without losing time or compromising

quality.

Is

rapid injection molding suitable for startups?

Absolutely. Startups benefit because they can create

functional prototypes affordably, test ideas quickly, and refine products

before committing to mass production. This reduces financial risk while

accelerating the path to market.

How

does rapid injection molding support faster launches?

It allows for earlier validation, quicker adjustments,

and faster approvals by producing ready-to-test parts in days rather than

months. This means businesses can launch products while competitors are still

preparing prototypes.

Does

rapid injection molding work with different materials?

Yes, it supports a wide range of plastics commonly

used in final production. This versatility allows companies to test real-world

conditions using the same materials intended for mass manufacturing.

Ready to prove your design with production-grade parts? Contact UTT Mould for rapid injection molding quotes, FAI, and short-run pilot builds