Every great product starts as an idea, but it may often feel like climbing a mountain to turn that idea into something practical. This ascent can be particularly challenging for businesses with little funding, short turnaround times, and the need to win over early clients. The right partners can make all the difference in this situation, and a lot of startups are finding that collaborating with plastic mold China manufacturers helps them advance more quickly.

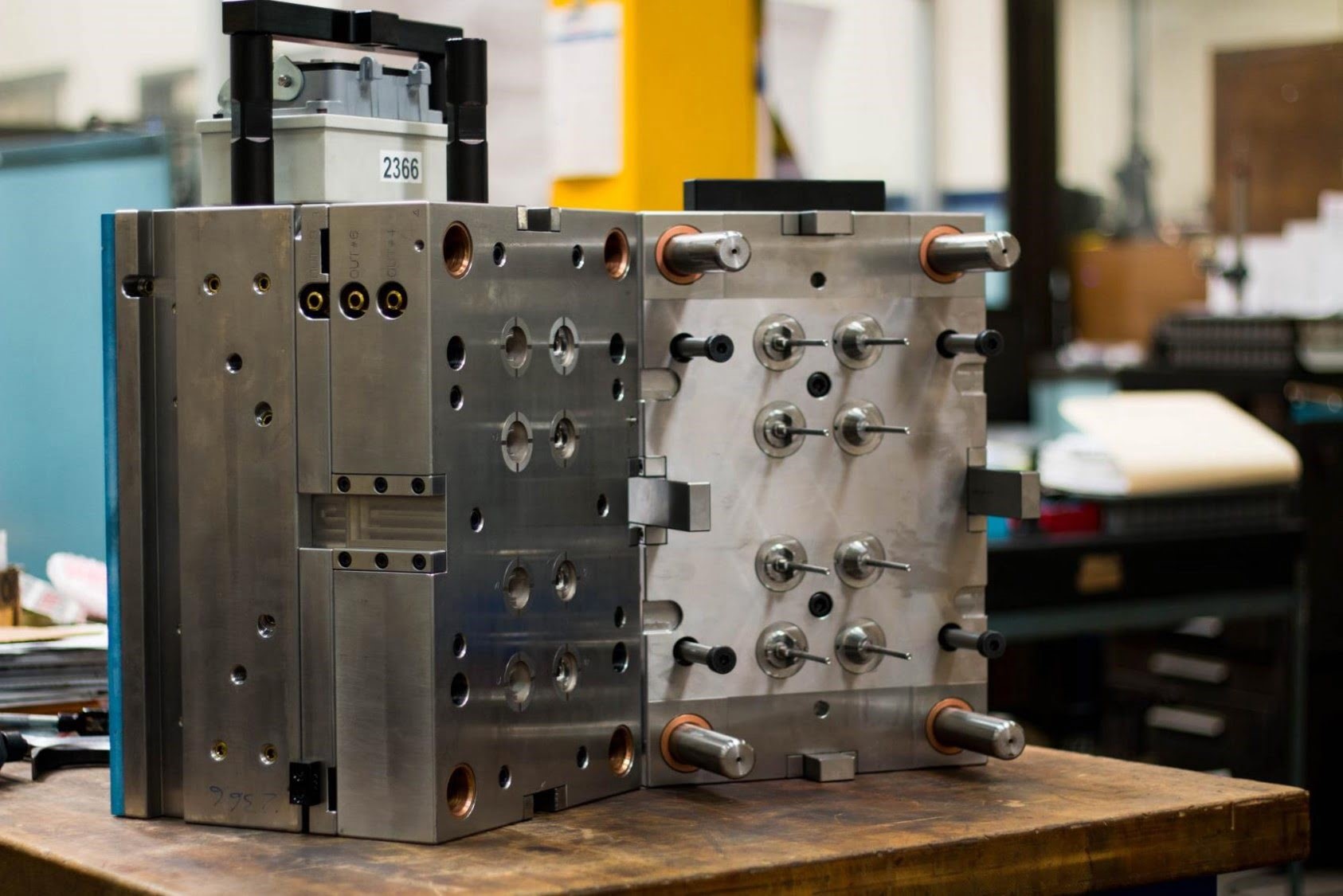

Speed and accuracy are essential for early-stage organizations; they are not extravagances. Plastic mold China partners have perfected the skill of striking a balance between the two. Their facilities include staff members that recognize the pressure small businesses face as they try to compete in crowded markets besides having cutting-edge equipment. Startups now possess completed prototypes and production-ready parts in record speed, rather than having to wait around for lengthy waits and unknown deadlines.

The appeal of working with seasoned mold makers is their versatility across several industries. The molders are skilled at turning digital ideas into robust components, whether a business is creating consumer electronics, home items, or car accessories. With this flexibility, small businesses are able to launch their products much faster than they had anticipated and cut down on trial-and-error cycles.

Budget management is one of the biggest challenges facing entrepreneurs. Mold producers help firms get most out of their investment by providing premium tooling at affordable prices. Getting access to craftsmanship and manufacturing capacity that enables a business to compete with larger businesses without depleting resources is more important than selecting cheap over good.

The collaborative approach is another reason why entrepreneurs use plastic mold manufacturing services. These manufacturers do more than just fulfill orders; they frequently offer advice on how to choose materials, enhance designs, and maximize production. As a result, they function more as an extension of the startup's own staff than as a vendor.

Molding is only the beginning of the adventure. Before committing to full-scale production, many firms that start with conventional plastic molding eventually turn to cutting-edge technologies like 3D printing China, which they use for quick prototyping and design validation. Startups gain speed and flexibility by combining additive technology with mold expertise, which speeds up their route to success.

Trying to sprint while still tying your shoelaces is what scaling a startup is like. Every choice you make either gives you momentum or slows you down. This momentum, dependable production, and insights that create stronger products, is provided by collaborating with plastic mold China specialists. For founders, it’s not just about manufacturing parts; it’s about finding partners that help translate ideas into realities that people can hold, use, and love.

Why

do startups choose plastic mould partners in China?

Startups choose them because of the combination of

speed, cost-efficiency, and expertise. Chinese mould makers are skilled at

turning concepts into products quickly, which helps startups move faster in

competitive markets.

Can

mould partners handle small production runs for startups?

Yes, many mould manufacturers in China are flexible

with order sizes. They support smaller runs for prototypes or pilot batches,

allowing startups to test the market before committing to full-scale

production.

How

do plastic moulds from China compare in quality with other countries?

China mould makers have advanced significantly in

quality. Many now use state-of-the-art equipment and materials, producing

moulds that meet international standards while still offering competitive

pricing for global businesses.

How

does 3D Printing China fit into the picture for startups?

3D printing complements traditional moulding by

enabling rapid prototyping and testing. Startups can refine their designs

quickly with 3D printing before moving into mould-based production, reducing

risks and saving time.