"Every outstanding product started out as a basic prototype." Ideas often come to entrepreneurs faster than resources. Finding a practical solution to make the thing a reality is equally as difficult as imagining it. Plastic mold China fills this gap by providing a link between creative ideas and products that are ready for the market.

Startups operate in an environment where survival depends on speed, flexibility, and accuracy. Emerging companies can see, test, and improve their concepts using a prototype made with Plastic Mold China without the high expenses of mass manufacturing. Producing a sample is simply one aspect of prototyping; other goals include identifying defects early, making effective design changes, and ensuring that the product meets user demands before making more significant investments.

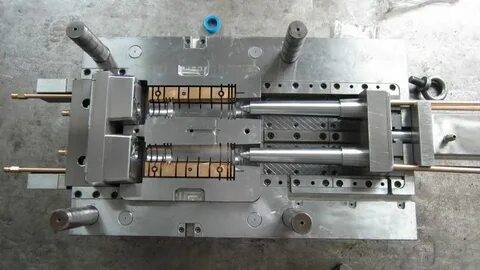

CNC production is a crucial component of this process. CNC machines provide a level of accuracy that is unmatched by manual techniques, expertly cutting complex forms into mold bases. This means that prototypes are more than simply placeholders for companies; they are functional models capable of undergoing limited trial runs, durability tests, and functionality testing. Prototypes are more accurate than ever before, thanks to the combination of plastic mold technology and CNC precision.

Few startups can afford to take the risk of creating molds without first testing. Prototyping with plastic molds significantly reduces that danger. Businesses might avoid investing in costly tooling that might later prove unsuccessful by evaluating designs early. This strategy gives entrepreneurs a competitive edge by cutting costs and speeding up time to market.

Prototypes inspire audacious thinking, and startups thrive on invention. Before completing the production-ready model, entrepreneurs can test usability, try out new materials, and experiment with unique product concepts using a mold prototype. Working with Plastic Mold China experts gives entrepreneurs access to knowledge and cutting-edge resources that streamline the process from idea to launch.

Prototyping is a continuous process. Startups often go through multiple iterations, with each version getting closer to the final result. With each iteration of modifications, entrepreneurs can make confident choices since CNC production guarantees that every refinement retains accuracy.

Plastic mold prototyping is essential for companies; it is not a luxury. It accelerates product introductions, lowers risk, validates ideas, and saves money. Even the most audacious startup concepts can become a solid, tested shape with the help of CNC Production technology and Plastic Mold China's experience.

What

is plastic mold prototyping?

Plastic mold prototyping is the process of creating

testable molds or sample products before committing to full-scale

manufacturing. It helps startups evaluate design, performance, and usability

without making large investments too early.

Why

should startups use Plastic Mold China services?

Plastic Mold China services are known for precision,

affordability, and fast turnaround times. Startups benefit from global

expertise, advanced technology, and cost-effective solutions that make

prototyping more accessible and efficient.

How

does CNC Production support mold prototyping?

CNC Production ensures high accuracy in mold creation

by machining detailed designs with consistency. This allows startups to test

realistic prototypes that closely resemble the final manufactured product.

Can

prototyping really reduce costs?

Yes. By catching design flaws early, startups avoid

investing in full-scale molds that might fail later. This cost control helps

stretch limited resources while still moving forward with product development.

Is

prototyping only for large-scale businesses?

Not at all. In fact, startups benefit most because

prototyping offers them a way to test ideas affordably, reduce risks, and enter

the market faster with validated, reliable product designs.

i