Speed is now the lifeblood of innovation rather than merely a competitive advantage. Businesses cannot afford to wait months for prototypes or parts that are ready for production in today's fast-paced industry. Rapid injection molding changes the rules in this situation by enabling engineers and designers to develop, test, and produce more quickly than in the past.

The process of developing a modern product is not simple. It's a continuous cycle of concepts, testing, comments, and improvements. This cycle is frequently slowed by conventional molding techniques, which result in expensive and lengthy lead times. However, rapid injection molding alters that rhythm by enabling teams to convert computer ideas into physical components in a matter of days rather than weeks.

Product developers may experiment, evaluate ideas fast, and address errors early in the design process because of this speed. The result? Smarter, market-ready goods were produced in record time.

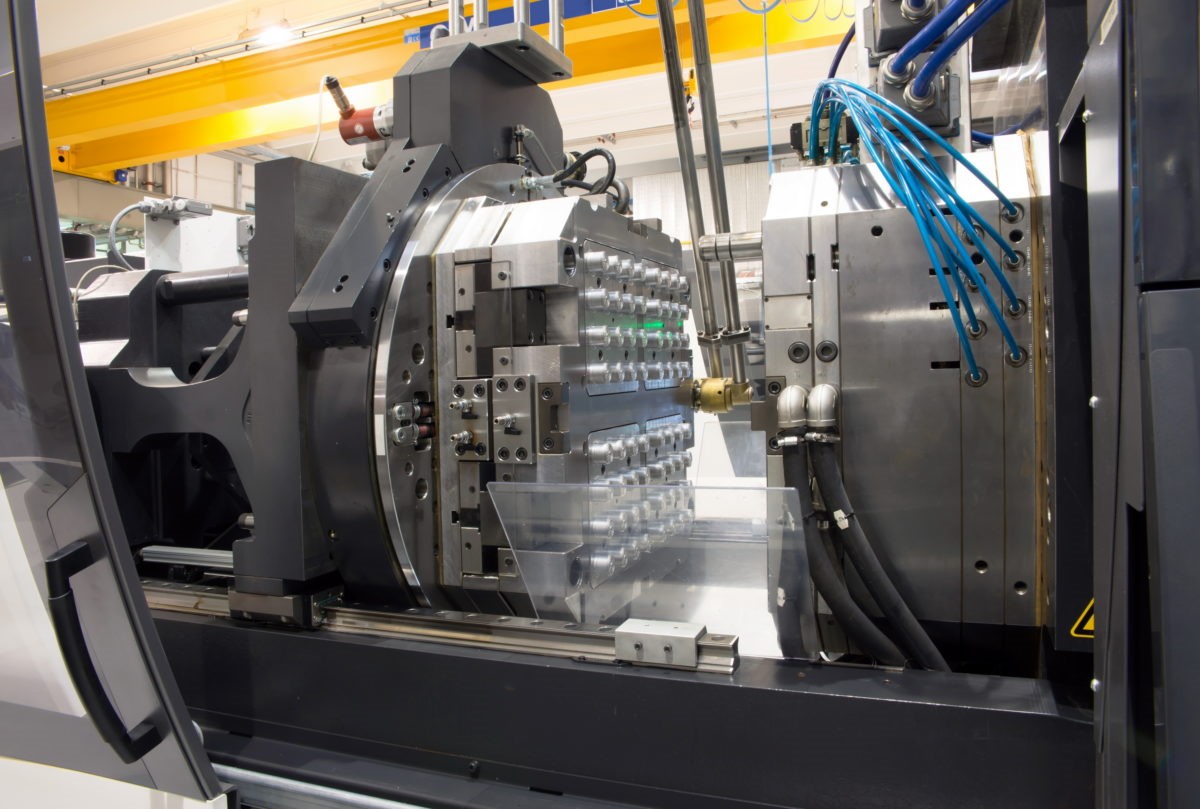

Let's say you have just finished designing a product. The first tangible sample would not be seen until weeks after tooling in traditional molding. Rapid injection molding greatly reduces this wait. Pieces may be manufactured nearly instantly using sophisticated CNC-machined aluminum molds after the design is approved.

Teams may go from prototype to low-volume production with little downtime because of this quick turnaround. You are making design choices supported by practical testing rather than depending only on conjecture. It is an act of innovation.

It's a common misperception that being "rapid" means compromising on quality. The accuracy of modern fast injection molding technologies guarantees a uniform surface polish and accuracy, making them ideal for both functional prototypes and final components. The switch from short runs to full-scale manufacture is smooth since the materials used are the same as those used in mass production.

Teams can improve geometry, assess performance, and get rid of any production issues before they become expensive mistakes since each iteration teaches something new.

Adaptability is key to agility, and teams may change course at any time, thanks to rapid injection molding. This procedure maintains development cycles flexible and responsive, whether it is modifying designs in response to client input or reacting to changes in the market.

Businesses that use this strategy frequently see lower expenses, faster launch schedules, and improved coordination between the production, marketing, and engineering departments. It fosters an atmosphere where concepts become solutions that are ready for the market rather than only existing on screens.

Rapid injection molding will continue to be a crucial component of agile product development as manufacturing and digital technologies continue to converge. It is expanding the realm of what is feasible in contemporary product design and manufacturing when paired with other fast-production techniques like sheet metal prototyping.

What makes rapid injection

molding different from traditional molding?

Rapid injection molding uses aluminum molds and

digital workflows to create parts faster, reducing production time from weeks

to days while maintaining high accuracy and material consistency.

Is rapid injection molding

suitable for large-scale production?

It’s ideal for prototypes and low-to-medium volume

runs. For very large production quantities, traditional steel tooling may be

more cost-effective after initial validation.

How does rapid injection

molding support agile development?

It allows teams to create, test, and modify parts

rapidly, aligning perfectly with iterative development models that depend on

constant improvement and feedback.

How does Sheet Metal

Prototyping complement rapid injection molding?

Both techniques accelerate early-stage product

testing. While molding is used for plastic components, Sheet Metal Prototyping helps test metal designs quickly,

supporting a complete agile development ecosystem.