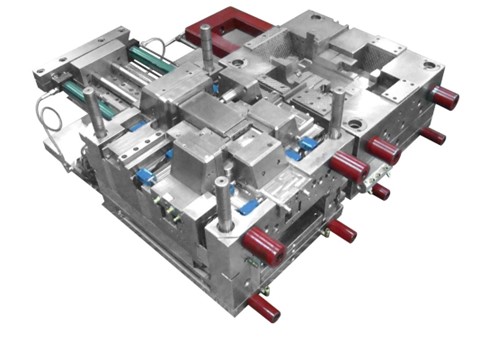

It takes a lot of work to transform concepts into thousands of accurate, superior products, but China molding makes it possible. Molding continues to rule mass production for everything from common home goods to car components because of its unparalleled accuracy, speed, and efficiency.

Molding is not just a manufacturing method, it is the basis for consistency. It is perfect for products that need to adhere to high quality standards because every curve, groove, and contour is accurately replicated. China Molding services are used by industries all over the world to ensure that every product satisfies exact standards while combining affordability and precise production.

The versatility of molding is one of its greatest benefits. It is possible to shape a variety of materials with amazing accuracy, including metals and plastics. Molding and CNC prototype testing are commonly combined by manufacturers to enable design refinement prior to full-scale production. Errors are decreased, material waste is decreased, and the finished product is guaranteed to be long-lasting and functional.

Production can increase quickly as soon as a mold is prepared. Molding makes it possible to produce thousands of identical parts nearly instantaneously, unlike human crafting or traditional assembly. This speed is crucial for industries with high market demand and constrained timeframes, such as electronics, automobiles, and consumer goods.

Although making molds costs money up front, there are substantial long-term advantages. Molding speeds up production cycles, minimizes material waste, and lowers labor expenses. China Molding Services may assist businesses in effectively reaching a worldwide audience by combining reasonable price with excellent output.

Besides molding, CNC prototypes let designers test and enhance concepts before moving forward with mass production. This guarantees that the products are not only the same but also completely performance-optimized. As a result, each batch produced has higher overall quality, fewer flaws, and less rework.

Molding is a quality and consistency guarantee, not just a production technique. It guarantees that items are produced effectively, accurately, and in large quantities when combined with CNC prototype testing and the knowledge of molding suppliers. Molding continues to be the gold standard for any company looking to ensure dependability in mass manufacturing.

What

makes China Molding ideal for mass production?

China Molding combines skilled labor, advanced

technology, and cost-effective production, allowing companies to manufacture

large volumes of high-quality products efficiently without sacrificing

precision.

How

does CNC Prototype enhance the molding process?

CNC Prototype allows testing and refining of designs

before mass production, reducing errors, minimizing material waste, and

ensuring the final products meet exact specifications.

Can

molding handle intricate or complex designs?

Absolutely. Molding excels at reproducing detailed

shapes consistently, making it suitable for both simple and highly intricate

product designs.

Is

molding cost-effective for smaller businesses?

Yes. Though molds require upfront investment, the

efficiency, reduced labor, and minimized waste make molding highly

cost-effective for businesses of all sizes.

How

does molding ensure product consistency?

Molding uses precise molds under controlled

conditions, producing identical units repeatedly. CNC Prototype testing further

refines designs, guaranteeing accuracy and reliability for every batch.

Ready to scale your product? Contact Uttmould, your expert China Molding partner, for a tailored quote today."