Have you ever wondered how the exact design of your phone case or the dashboard of your automobile gets formed? The key is found in plastic molds, an intriguing fusion of engineering, design, and workmanship that subtly drives our contemporary way of life.

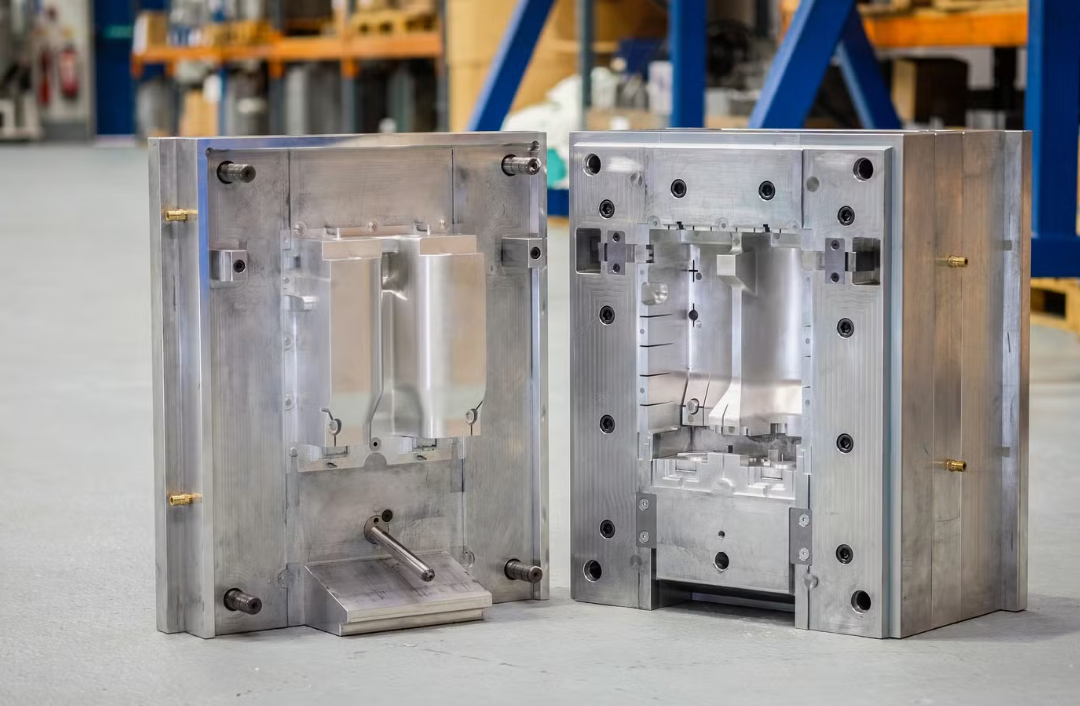

All products start as an idea. However, it takes more than just imagination to make that concept a reality. It demands accuracy. The core of this change is plastic mold.They are carefully engineered cavities, often made of steel or aluminum, that specify how melted plastic flows, cools, and solidifies into a finished product.

Consider this: well-designed molds are responsible for the sophisticated water bottle lids, the ergonomic handle of your kitchen gadgets, and even the stylish case of your smartphone. Manufacturers have turned this procedure into a fine art by combining cutting-edge technology with years of technical expertise.

Plastic mold in China requires accuracy, consistency, and innovation besides mass manufacturing. Previously unthinkable elaborate patterns are now achievable because of advanced molding techniques. Engineers can precisely forecast the behavior of molten plastic using high-precision CNC machining and cutting-edge mold-flow models, guaranteeing that every millimeter matters.

Businesses are able to satisfy widespread demand while preserving their creative integrity because of this degree of control. Actually, a lot of international businesses work with skilled mold manufacturers in China because of their ability to combine accuracy, quality, and affordability in a single procedure.

Although it's simple to ignore, mold affects practically every aspect of our daily lives. From life-saving medical gadgets to the little parts in your laptop, these molds enable sustainable and effective mass production. Design and testing come first, then the mold is machined, molten plastic is injected, cooled, and the final product is ejected. Each step must be closely watched to guarantee flawless form and texture.

The development of molding continues after this. Molds are getting progressively more accurate and versatile as automation and smart manufacturing gain prominence. Manufacturers can now create intricate designs with little waste, thanks to digital design and real-time monitoring, opening the door to a more intelligent and sustainable future.

China continues to lead the world in this area due to its ongoing innovation as well as its production capacity. Plastic Mold China keeps raising the bar for accuracy and dependability worldwide, whether creating molds for consumer electronics, medical devices, or car parts.

The importance of molds will only increase as we progress toward a world dominated by design and creativity. They are the unseen designers behind the goods we use on a daily basis, from commonplace equipment to innovative technologies. Moreover, Prototyping in China continues to provide the speed and knowledge required for firms looking for quick development to realize ideas more quickly than ever before.

What is a plastic mold used

for?

A plastic mold shapes molten plastic into specific

forms, allowing manufacturers to produce consistent, high-quality items ranging

from industrial components to everyday consumer goods.

What materials are commonly

used for plastic molds?

Steel and aluminum are the most common materials due

to their durability, resistance to heat, and ability to maintain precision

through repeated molding cycles.

How long does it take to make

a plastic mold?

Depending on complexity, creating a mold can take

anywhere from a few days to several weeks. The process involves design,

machining, testing, and refinement before it’s production-ready.

How does prototyping support

mold design?

Prototyping allows manufacturers to test product

designs before committing to full-scale production, minimizing errors,

improving performance, and reducing overall development time.

Ready to transform your product idea using world-class Plastic Mold China expertise? Contact Uttmould today for a consultation on your custom tooling needs.