Molding is the process of utilizing molds or castings to shape materials, usually rubber, metal, or plastic, into exact components. It is the backbone of industries, including consumer products, electronics, cars, and medical devices. If you work in any of these industries, you are well aware of how rapidly expenses can mount up. The good news is that you may reduce costs without sacrificing quality.

In this blog post, you will find five practical and effective techniques to reduce the cost of China molding manufacturing.

The material you choose impacts:

● Cost

● Durability

● Manufacturing speed

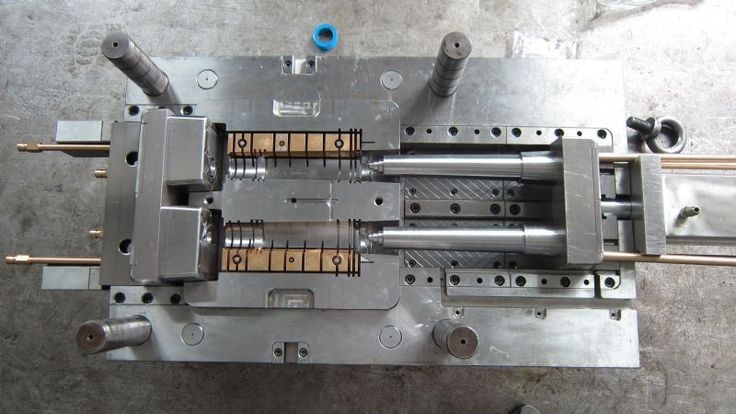

Many companies make the mistake of selecting cheaper materials that wear rapidly and require expensive replacements. Invest in hardened steel molds if your manufacturing volume is large, as they are more durable and precise. Aluminum molds are more economical and effective for small volumes. The secret is achieving a balance between long-term worth and short-term savings.

The majority of cost-saving opportunities lie in design. Rejected components, lengthy cycle times, and material waste are the results of a poorly conceived design. Before starting production, always do design-for-manufacturing (DFM) tests. This stage guarantees that your product can be shaped effectively and without needless complication. Think about:

● Reducing sharp edges and undercuts

● Minimizing differences in wall thickness

● Simplifying part geometry

By reducing production time and material waste, these little design changes can save thousands of dollars.

Part removal, trimming, and checking are repetitive jobs and rely on a high level of precision, so automation can handle them. The investment of automation is quickly paid back by reducing your costs: lower turnaround time and reduced human error. Just a portion of the process - loading/unloading and trim removal - would increase consistency and reduce cycle time. If you can identify and have your most capable talent doing higher-value type jobs, you can do more with less.

By taking time on a regular basis to check, polish, and clean, you are able to see if there is any wear or tear before it becomes an issue. Schedule the inspection regularly (probably a few thousand cycles or so between each one). The cost of replacing a worn component due to wear is significantly less than the cost of repairing a mold. A clean and regularly inspected mold will ultimately produce a higher quality product, due to less wasted materials or rework (both of which add cost).

Always choose experienced suppliers who offer competitive pricing without sacrificing quality. With high-quality materials and efficient manufacturing techniques, they can deliver superior results for less. For instance, China molding companies are well-known for fusing cutting-edge technology with affordability, which makes them a top option for international corporations looking for reliable manufacturing at a reduced cost.

In molding, cutting costs doesn't mean taking shortcuts! It just requires working more efficiently. You can protect both the quality and the budget of your product by focusing on the points mentioned in this blog. Additionally, if you're looking for other precise solutions for your parts, you might want to consider CNC machining in China, which provides fantastic value for detailed, higher-quality components.

How can I cut down on waste during mold production?

To reduce needless waste during manufacturing, optimize your design, employ accurate temperature control, and recycle discarded material wherever you can.

What is the best approach to maintain molds?

To prolong the life of molds, clean them frequently, check for wear, lubricate moving parts, and store them correctly when not in use.

Is automation beneficial for small-scale molding?

Yes, even small-scale automation, such as robotic arms or sensors, may boost production speed, reduce mistakes, and enhance accuracy.

How can I decide between molds made of aluminum and steel?

Steel molds are ideal for long-term, high-volume applications. Because aluminum molds are less expensive up front, they are ideal for small runs or prototypes.

Can I save money by outsourcing the creation of molds?

Yes. You may reduce expenses without sacrificing product consistency by outsourcing to reliable international partners with established quality standards.