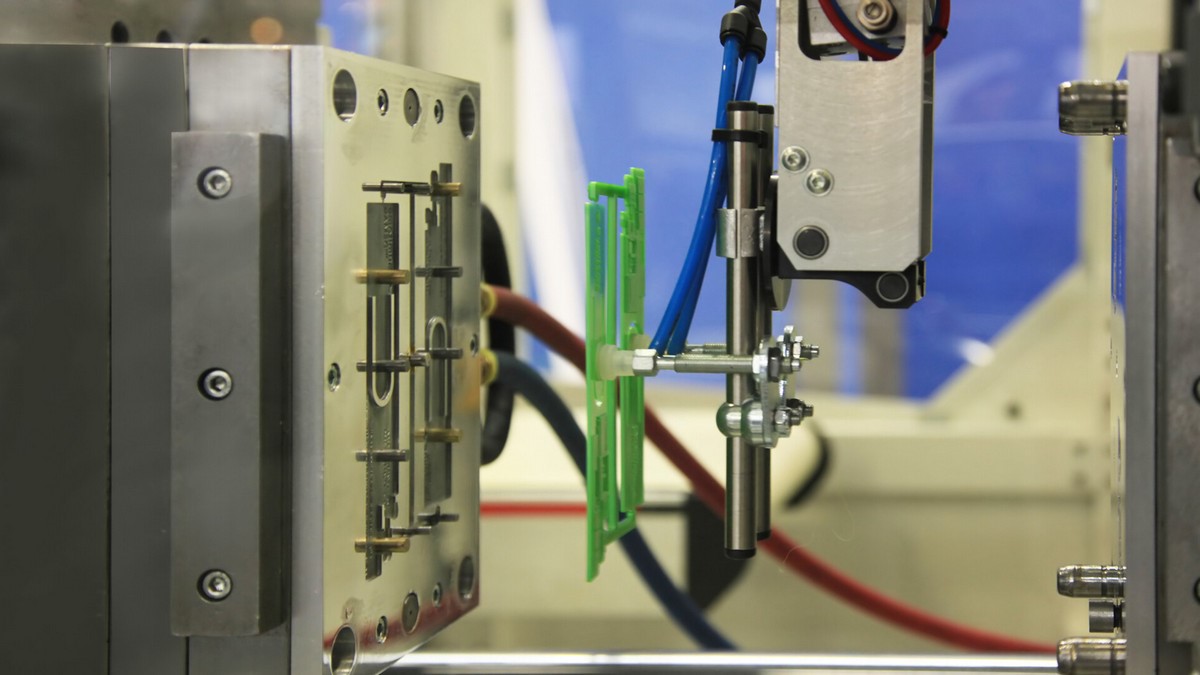

Imagine being able to produce thousands or perhaps millions of identical plastic parts with the same quality, shape, and finish in a matter of days. That's how China plastic injection molding works. This approach is not only useful for companies looking to scale up quickly, but it frequently becomes the foundation of large-scale production.

Choosing plastic injection molding gives you access to a number of benefits that become increasingly noticeable as production quantities increase:

● Per‑unit cost drops drastically: Making a mold can be expensive up front, but once the mold is in place, making more parts is surprisingly affordable. Production becomes much more efficient as volumes increase and the cost per part decreases.

● Speed and volume go hand in hand: Modern injection molding machines can make numerous identical parts in a single run, and they can fire off components in a matter of seconds or minutes with multi-cavity molds. Large-batch manufacturing is timely and feasible because of this pace.

● Uniform quality and precision, every time: Dimensional consistency and exact tolerances are consistently maintained because every part is made from the same mold. You get the same level of design accuracy whether it's the first or the thousandth item.

● Low waste and resource‑efficient production: Unlike subtractive techniques, injection molding uses only the material required, and any excess plastic is frequently recyclable. This lowers raw material prices and material waste, which is crucial when producing in large quantities.

● Design flexibility meets scalability: It is possible to mold elaborate or sophisticated plastic pieces with curves, undercuts, and tiny details effectively. Scaling doesn't eliminate this flexibility; massive production runs can nevertheless reliably produce intricate, delicate pieces.

Many businesses use "Rapid Prototyping Services" to improve their designs prior to pouring thousands of parts via injection molding. These services help identify design issues early on and save time and money by assisting with the creation of early versions, whether functional or conceptual.

You lower the possibility of expensive mistakes once mold tooling and production start by using prototypes to validate form, fit, and function. This facilitates the transition to mass production, particularly if you intend to scale quickly.

Injection molding provides predictability for manufacturers growing their product lines or startups introducing consumer goods. You may place orders for batches of 10,000, 100,000, or more without requiring a correspondingly greater workforce, more overhead, or a significant logistical ramp-up after the setup is complete. You receive cost-effectiveness, speed, and quality, which results in higher profit margins, dependable delivery, and the capacity to quickly satisfy market demand.

Plastic injection molding is the most practical and reliable way to expand, whether your goal is to produce hundreds or hundreds of thousands of plastic components. You have a recipe that promotes expansion without turmoil when you combine that with international manufacturing centers that offer competitive pricing and supply-chain strength.

Doesn’t mold tooling cost too much to

justify injection molding?

It's true that the mold tooling does cost money up

front. However, after that, the cost of each extra part is far lower, and when

you create in large quantities, the cost spreads out, making each piece

significantly less expensive.

Can injection molding handle complex

designs or only simple shapes?

Yes, it can manage difficult geometries, including

undercuts, fine details, and irregular shapes with precise molds. Large-scale,

reliable replication of even complex designs is possible.

Is plastic waste high in injection molding?

Not at all. This procedure usually uses just enough

material for each item, greatly reducing raw material waste because surplus

plastic is frequently reusable.

Why use prototypes before going full‑scale

manufacturing?

Prototypes are used to test design, fit, and functionality before purchasing

mold tools. This lowers the possibility of design errors, guaranteeing more

efficient and error-free large-scale production.

Is small‑batch production practical with injection molding?

Injection molding works best when production is done

on a large scale, but it is typically not perfect. The cost per part is still

expensive for small batch or extremely low-volume runs because setup and

tooling expenses are not distributed over numerous units.